It’s always fascinating to travel using the craft you’ve made by yourself, although building a plywood boat is not usually the ideal option for boaters because it needs a significant amount of time, work, and various skills. However, many people still enjoy constructing their own plywood fishing boat since it is the most frequent and enjoyable way to begin boating.

In fact, creating homemade plywood boat designs has long been preferred by expert boat owners and DIY enthusiasts. Building a DIY plywood boat, like many other crafting projects, may save a lot of money while also being a great learning experience, despite some difficulty in procuring supplies and mastering woodworking techniques.

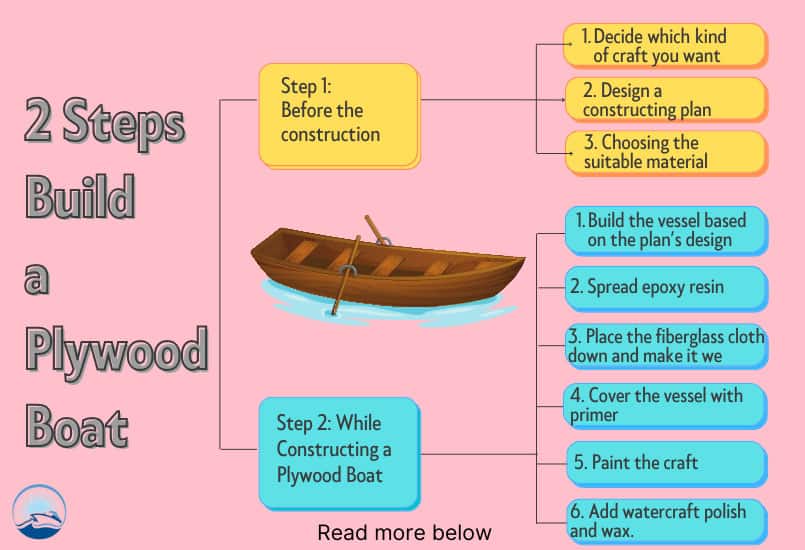

If you are looking for such simple instructions on “How to build a plywood boat?”, this article is perfect for you! In the post, we will not only provide necessary knowledge relating to plywood boat construction but will also compile a detailed tutorial on ways to build a wooden boat step by step according to the instructions below:

- Spread epoxy resin

- Place the fiberglass cloth down and make it wet

- Cover the vessel with primer

- Paint the craft

- Add watercraft polish and wax.

Moreover, other tips on creating DIY vessels from expert plywood boat builders and further notices while purchasing the right materials for the construction will be highlighted so that you and other sailors can proceed this process without too much difficulty. Continue reading to learn more!

Table of Contents

The Best Plywood Material for Boats

As previously said, the material used in the building of boats must be carefully considered. As a result, this material should be very resistant to water and dampness. Plywood is now the most often used timber material in boat construction. It is critical to utilize high-quality materials to guarantee that the vessel lasts as long as possible.

In our opinion, Oukume plywood and marine birch plywood is the best material for boats. These types of wood contain components that support the floating ability of the craft, making it stronger and tougher while handling different weather and water conditions.

On the other hand, you will also need to prepare other necessary equipment and tools for the construction process, such as marine glue, epoxy resin, fiberglass cloth, sander, polish and wax, wood saw and tape.

Main Parts of a Plywood Boat

To understand what you need to do when constructing a plywood boat, it is necessary to learn about its main elements and the base structure of the vessel. Here in this part of the post, we will deliver basic knowledge about each boat’s component and its features. Continue reading to find out more!

1. Spine structure

The backbone is the most critical component of the boat. It is the fundamental construction block of the boat. To build a boat, you must first complete the spine. Then you must go on to the next step. The spine must be produced in one component as long as feasible.

However, because it is difficult to acquire monolithic material (wood) for boats of 10-15m length, the foundation of the appropriate length can be obtained using the transversal bonding method as features added in the length’s direction to lower the cost. The spine is often made from the wood of chestnut trees, as this material is mostly recommended by professional carpenters.

2. Ballast Spine

Ballast is the element of the boat that permits it to stand properly on the water’s surface. Thanks to this component, the boat will not capsize. The ballast spine, typically constructed of lead & iron, is attached to the fundamental spine via salmon bolts.

3. The bow

This section, which makes up the front of the boat, is sloped. It is often composed of oak, chestnut, or ash wood. The bow foundation (front half of the boat) can be constructed from a single piece or just by joining many parts together.

While it is constructed as a single component, 12-16 mm sections are put on top of each other and crushed using the mold. When the front of the craft is composed of two components, they are joined together by glue or bolts.

4. The stern

It is constructed in the same method as the boat’s bow. It is often framed from chestnut and oak and is joined to the spine by a connecting device known as a scorpion. It can be composed into single or double segments depending on the scenario. While being created of two components, they are glued and bolted together.

Step by Step to Build a Plywood Boat

1. Before the construction

Before you proceed with constructing your wooden vessel, there are a few steps you need to take in order to design a proper plan for building a plywood boat efficiently. Following these guidelines below and learn more:

- Decide which kind of craft you want

The first stage is to devise a plan for your boat-building endeavor. Selecting the type of vessel you want, such as a plywood fishing boat, can make all the other processes much easier to arrange.

For your initial construction, it may be best to choose something small, at least until you’re sure of your constructing abilities. Just carefully plan ahead of time for anything you can. Don’t worry about covering everything; simply prepare what you can, and things will be much simpler afterward.

- Design a construction plan

The first and most important thing you would want is a boat plan. There are unlimited plans accessible, but it is best for you and your project to get designs from a trusted source. Professional boat plans outline how to build a proper boat step by step and thus are simpler to understand than free plans, which may be out of date.

- Choosing the suitable material

To save time and effort, it’s a good idea to utilize marine plywood for the whole boat. Since marine plywood has nearly no voids, this should make the job easier since you won’t have to coat as much space with resin. You also might end up wasting more if the project requires more resin than you anticipated.

2. While Constructing a Plywood Boat

- Build the vessel based on the plan’s design

Following that, construct the boat itself using the boat designs you obtained. If this is your first construction, try to keep as closely to the blueprints as possible. Even little variations can have far-reaching consequences that you will be unable to anticipate. Before beginning assembly, go through the blueprints again and make any necessary changes.

- Spread epoxy resin

Add epoxy glue over the whole surface of the boat. The most critical aspect of applying epoxy resin is to produce a completely smooth texture. If there are any gaps or cavities on the wood surface, you must fill them with resin. To flatten everything out, sand the area. Allow the resin to cure before moving on to the next step.

- Place the fiberglass cloth down and make it wet

Cut the fabric to size and let it rest for several days before ensuring a smooth finishing surface. Flatten the surface of the material once it has softened to iron out any folds or creases. Smoothing can be done by hand or using a tool.

You might use duct tape to stick the fabric in place while you smooth it; repeat this process several times until the material is wrinkle-free. This is necessary to maintain a consistent finish. Allow the flattened cloth to sit overnight before wetting the surface. As soon as the cloth has been completely dried, it’s ready to be reused in the next step.

Make another run with the fiberglass cloth before soaking it to ensure that the entire surface is flat. Wet the surface of the fabric with a thin coating of epoxy glue. Before it dries, make sure the surface is smooth.

- Cover the vessel with primer

The boat will next be painted using fiberglass paint. Putting primer first, two or three applications should be enough. Make sure to apply the primer with care; a consistent coat is essential for a great finish.

Work in portions so you can devote adequate time to the primer. Allow the first priming layer to dry before applying the second coat. Add your paint after the priming layers, and, like with the primer, work in tiny parts to keep the paint’s working time bearable.

- Paint the craft

Paint the craft horizontally with a brush. This will result in a clean layer of paint, but the trick is to be quick with the second paint, so working in segments is ideal.

Color the whole vessel’s surface, paying special attention to make the coat as even as possible. We prefer semi-gloss paint since it has a durable finish.

- Add watercraft polish and wax.

The last stage is to polish as well as wax the boat’s surface. This will provide the boat with a gleaming sheen, which will make the watercraft stand out while also protecting it from severe sea conditions. Try to follow the directions that came with your chosen product.

You are now finished. All that remains is for you to set sail on your own DIY plywood boat.

Conclusion

Self-constructing a plywood boat is a fun and satisfying procedure for people who have a tight budget yet still wish to have a memorable cruising experience. We hope that the information and suggestions provided above will assist you in building your homemade plywood boat successfully and efficiently. As a result, going on a wonderful excursion with your own DIY plywood boat is no longer an impossible dream!

Did you enjoy the article on how to build a plywood boat? Do you want to add anything else? Please let me know and leave a comment below.

Ten years of enjoying countless trips on boats never made me love them any less! So I am here to put all those experiences into good use for other boaters who want to have a safe and fun trip with their friends and families.