If you own an aluminum boat, it doesn’t mean it will be immune to the wear and tear of regular use. Despite the material, a boat would still demand care and maintenance like other vessels. You should do this process for the longevity and efficiency of your boat.

Leaking seams or rivets are the common issues you would encounter. So buying the best sealer for aluminum boats is essential. The right techniques for using this product will help you restore some damaged parts. Better fix them at an early stage before they get worse.

This article will help you choose the aluminum boat sealer for your needs and style. Hopefully, the chosen product will help you maintain your aluminum boat in optimum condition.

Travaco Marine-Tex RM330K

| + Easy application |

| + Resistant to abrasion and marine parasites |

| + Strong yet flexible coating |

Amazing GOOP 5400040

| + Sticks well on aluminum surfaces |

| + Forms a waterproof seal |

| + overs cracks, holes on the rivets,… |

Hy-Poxy H-450

| + Two-part sealer for effective use |

| + Creates waterproof seal |

| + bsorbs stress from movements |

Table of Contents

- Top 10 Sealer for Aluminum Boat Reviews

- 1. Travaco RM330K Gluvit Epoxy Sealer

- 2. Amazing Goop 5400040 Coat-It Sealer

- 3. Hy-Poxy H-450 Aluminum Putty Repair

- 4. Flex Seal Liquid Rubber

- 5. Star Brite Epoxy Putty Stick

- 6. 3M Marine Adhesive Sealant

- 7. TotalBoat Penetrating Epoxy Sealer

- 8. GE Sealants & Adhesives GE5050 Sealant

- 9. Flex Seal Spray Rubber Sealant Coating

- 10. TotalBoat Aluminum Boat Leak Sealer

- What is Marine Sealant and How Does It Work

- Types of Sealers of Aluminum Boats

- Benefits and Drawbacks of Using Sealant for Aluminum Boats

- Buyer’s Guide

- Care and Maintenance

- Frequently Asked Questions

- Conclusion

Top 10 Sealer for Aluminum Boat Reviews

1. Travaco RM330K Gluvit Epoxy Sealer

This product is not just an aluminum boat leak sealer as it can also work on steel, fiberglass, and wood. Protecting the hulls and decks as well as sealing leaky seams and rivets are its jobs.

I owe this sealer as it saves my aluminum boat from being dysfunctional. A well-rounded sealer like this one is what I need! And, cases are different from person to person, so this sealer is available in different quantities. You can get the necessary amount for a specific aluminum boat leak repair.

The good news is that you do not need to drill and re-revit the entire boat to seal its leaking rivets. If you are a newbie to this kind of thing, fret not as it is easy to apply as you only need to use a brush and let the finish dry.

Once the sealer is dried, it forms a hard protective coating that flexes along with the hull’s movements. You can make fillings for minor pinholes and cracks. Hairline cracks can be sealed too.

This sealer is also like a barrier for water absorption and galvanic corrosion, so you can depend on its sealing strength to last for a long time.

This Gluvit aluminum boat sealer provides resistance to abrasion after applied. Therefore, you can protect the sides and bottoms from getting damage from some rocks or what’s underwater. Marine parasites won’t be allowed to injure your boat as well.

- Works on aluminum, steel, fiberglass, and wood

- Easy application: use a brush and let the finish dry

- Shields against water absorption and galvanic corrosion

- Strong yet flexible coating

- Resistant to abrasion and marine parasites

- Requires painting the dried sealer for UV protection

2. Amazing Goop 5400040 Coat-It Sealer

I use this as an aluminum boat sealant because of its favorable qualities. This sealer is made to stick well on aluminum so that a grinder can’t even remove its finish. Every boat owner can rely on this product to fix the issues of their boat rivets.

This epoxy sealer has a thick texture, but it’s still easy to use. Start by pouring it into a container, then stir the solution before applying it. You can use it to cover cracks and holes on the rivets. I tried it to patch the holes in the gutter, and it worked well.

The seal needs 10 to 12 hours to dry and become waterproof, making it the most favorite sealant for aluminum boats. You can paint the surface where you apply this sealer to make the color of the whole boat even.

Normally, a pound of this sealer can cover 20 square feet. But it would depend on the surface porosity and the amount or thickness that you apply. The formula is composed of ceramic beads to resist abrasion. It has graphite for lubricity and Kevlar fiber for the necessary toughness. You can rely on it to remain robust while you glide on rocks and debris. Thus, the boat’s truck bed or bottom is protected all the time.

- Sticks well on aluminum surfaces

- Easy application: pour and stir the solution before applying

- Covers cracks, holes on the rivets, gutters, …

- Forms a waterproof seal

- Potent formula with ceramic beads and graphite

- Performs well on fiberglass and wooden parts

- The finish needs to be painted for even surface

3. Hy-Poxy H-450 Aluminum Putty Repair

The items in this putty repair kit are formulated to treat aluminum surfaces. I’m glad I took the chance to have it on my aluminum boat to fix some issues and prolong its life. Aside from the boat’s aluminum hull, it has a wide application.

There are two tubes in this kit, containing hardener and resin with an exact ratio for mixing. Each of them is filled with real aluminum particles, premium quality additives, and modified curing agents.

This sealer is best to seal aluminum boat small issues as you can avoid wasting the substance. I can easily keep the tubes in a toolbox whenever I haven’t used up the entire tube.

This epoxy metal weld is developed for aluminum surfaces. It is not only for repairing issues on boats. You can also use it on pumps, radiators, castings, valves, tanks, HVAC pipes, water jackets, and more. It will also leave a seal that is rust-resistant and non-magnetic.

What I like the most about the finish of this sealer is the possibility of modification. You can easily paint, drill, tape, or sand the surface without damaging the seal. I was so surprised to see that it remains its gray shade after polishing.

- Comes with an exact ratio of hardener and resin for mixing

- Best at repairing small issues

- Creates a non-rustic and non-magnetic seal

- Various applications: aluminum boats, pumps, radiators, tanks, etc

- Can be drilled, threaded, sanded, or painted over

- Needs to stir for several minutes for vertical use

4. Flex Seal Liquid Rubber

This product from Flex Seal is in liquid form, so you can control the application the way you want it. You can convert it to an aluminum boat sealer paint if you put it with a brush. Also, it is a breeze to roll or pour the liquid on the aluminum surface. Expect a straightforward application as you can smoothly cover some cracks or holes.

It makes me confident to go fishing on rivers and lakes after fixing some holes on my aluminum boat. The sealer is also flexible as it is made of rubber. No water, moisture, and air can pierce into it. It resists UV rays, chemicals, and mildew too. Also, I no longer need to be concerned with corrosion and rust on my boat.

It feels great knowing that I use a safe product as this liquid sealer is non-flammable, non-toxic, and non-hazardous. The content is safe for all living things like plants and animals. But I still wear gloves when applying so I can do a quick washing of my hands.

This liquid sealer may develop skin due to air exposure. You can separate it from the rest of the solution to prevent it from turning lumpy. However, you may not need to do it as it is available in different quantities such as one gallon, 32 oz, and 16 oz. Just buy the amount that you need.

- Can be applied in different methods: Brush, roll, or pour

- Forms a watertight rubber coating

- Resistant to UV rays, chemicals, and mildew

- Prevents rust and corrosion

- Safe use with a non-flammable, non-toxic, and non-hazardous formula

- The formula might turn into a skin-like form when exposed to air

5. Star Brite Epoxy Putty Stick

I like this Starbrite Epoxy Putty Stick for several reasons. It is like a lump of clay that you can mold on the areas that need fixing. You have to knead it first for around two minutes to make the color even. When applied, the solution goes smoothly in filling the gap or holes and cracks. Then, you can remove the excess.

The duration that it needs to bind is 5 to 10 minutes. I found out that it can be as hard as steel in just a matter of half an hour. After the curing is complete, you can drill, sand, or tap it. The finish is not too visible as it’s like camouflaging with the boat.

Once it has dried, the sealer clings well on the surface and stays in place, meaning you just make a waterproof coating for aluminum boats! The product leaves a permanent repair and works all the way underwater. When there’s an emergency, you can use it right off the bat.

I was able to apply it on a wet and slowly leaking area. I was so amused to see its effects. This sealer saved me from a huge problem at that time. You may also use it for manifolds, drive units, and mufflers as it can withstand high temperature and pressure.

Its effectiveness comes from the powerful additives that are capable of cutting through anodization and oxidation. Despite weathered aluminum, the bonding that it establishes is tough and dependable. In case you have sensitive skin, you have to wear gloves during application.

- Smoothly fills in cracks and holes

- Leaves a waterproof coating

- Creates permanent repair within an hour

- Can be applied to wet and slowly leaking areas

- Forms a touch bonding to withstand weathering

- Should wear gloves to protect sensitive skin

6. 3M Marine Adhesive Sealant

I’m glad to have found this marine adhesive sealant as it provides permanent sealing. What gives it a long-lasting formula is the strong polyurethane polymer. It remains tough even when exposed to saltwater and other harsh weather conditions.

In truth, you can make permanent coating and repair for your boat’s interior and exterior damages, thanks to this product’s fantastic bonding. And you should always handle it with care. I’ve used this as a sealant twice, and so far, the seal doesn’t come off.

This sealant also adheres to wood and fiberglass, thus ideal to fix other parts of your boats and RVs. However, the manufacturer advised not to use it as a seam sealer on teak decks.

On the other hand, this sealant creates a coating that is resilient yet flexible. That explains why the boat’s movements do not displace its dried finish. Hence, you should not worry about the sealed parts being broken due to engine vibration or sudden shock.

- Long-lasting formula with polyurethane polymer

- Can be used in saltwater

- Resistant to weather elements

- Makes a permanent coating or repair

- Flexible against movements

- Shouldn’t be used as a seam sealer on teak decks

- Curing takes 5 to 7 days

7. TotalBoat Penetrating Epoxy Sealer

This two-part epoxy sealer is known to harden rotted wood. With its amazing abilities, I didn’t think twice when using it for my aluminum boat. The finish that I can create from this product is like paint and varnish but sticks much better.

You can cover up cracks and small holes on your boats well because of its strength. Also, this marine-grade epoxy is designed to penetrate the wood and to protect surfaces from mildew, mold, and fungus. Indeed, these features will support the necessary repairs on your aluminum boat.

Since going boating or fishing means exposure to different exterior elements, your boat needs protection from water. Luckily, this sealant can form a shield that prevents moisture intrusion.

But there’s more to expect from this sealer. It is available in two formulas that consider different temperatures. The regular one works on temperatures ranging from 65 degrees to 90 degrees Fahrenheit. The other one is for cold weather when the temperature is around 40 degrees to 65 degrees. Thus, you can get a suitable solution wherever you are.

Using this sealer is no sweat as it has no harsh fume and VOC. Cleaning up with water and soap is easy too. You may also sand the finish to make the surface smooth then do the painting.

- Sticks much better than paint or varnish

- Marine-grade epoxy prevents mildew, mold, and fungus

- Works well on both wooden and aluminum surfaces

- Protects surfaces from water intrusion

- Contains no harsh fume

- Two options for warm and cold weather

- Need to mix the resin and hardener

8. GE Sealants & Adhesives GE5050 Sealant

This next option on our list is a silicon sealant for aluminum boats. It creates a seal that is durable and can stay on the boat for a long period.

This sealant proves its durability by having strong adhesion and excellent flexibility. Hence, you are assured of a long-lasting seal, which is essential for maintaining an aluminum boat in good performance. This weatherproof and waterproof seal is very useful in sailing and boating.

I’ve used my aluminum boat a couple of times after I used this sealant. It can withstand water and moisture, thus remains intact. I can say it provides excellent protection. Weather and temperature can’t bring it down as the result is resistant to UV degradation and freezing point.

Not to mention, this solution doesn’t blemish any kind of metal, including aluminum and high-ends ones like bronze, nickel, and chrome.

The application is tack-free, and it will be ready in 30 minutes. The seal it creates would be fine when you expose it to rain as well as water after the given time. It implies that you can apply this sealer even though you’re in the middle of the lake or river.

- Makes a durable repair and seal

- Strong adhesion and excellent flexibility

- Weatherproof and waterproof

- Doesn’t blemish metal like aluminum

- Effortless application on porous, non-porous, dry, or wet areas

- Has a sticky texture, so wearing gloves is necessary

9. Flex Seal Spray Rubber Sealant Coating

Suppose you are first-time users or boat-owners that struggle to apply sealers many times. The good news is, things can be much easier with this spray rubber sealant.

Once this aluminum boat rivet sealer dries on the surface, you can paint over it. That’s why it’s popular among DIY projects as well as arts and crafts.

This sealant has many uses like covering cracks and holes on your aluminum boat as it seeps right into those damages. You can have it on the top of your house, on trailers, and when going camping.

Since it has a wide application, the efficacy is not exclusive to dry surfaces. It can stick well on wet parts of your boats easily. The finish can adapt to different weather and temperature. In hot weather, you don’t have to be worried about dripping and sagging of the finish. When winter comes, it can afford no peeling or cracking.

- Easy and convenient to use by spraying

- Can be painted over once it dries

- Can hold on to a wet or dry surface

- Seeps into small cracks and holes

- Prevents corrosion forming on aluminum

- Should be applied in a ventilated area

10. TotalBoat Aluminum Boat Leak Sealer

The best way to seal an aluminum boat holes, leaks, and cracks are by using this two-part sealer. Nonetheless, this sealant is easy to use with no mess to create a good seal.

There’s a standard caulk gun for the cartridge to fit in. There are two cartridges, and what is inside them? Well, they contain resin and hardener. Pop a cartridge into the gun to connect the mixing tip. Point it to a certain area and pull the handle.

Once the gun and 25-ml cartridge are connected, you can release three or four beads. You have the right mixture and an exact ratio of 1:1 because of this process. With this design, I can smoothly apply it without any mess. Also, getting things right will give you a proper cure as well as a waterproof seal.

The formula is sag resistant, thus ensuring no dripping on holes and seams. For maximum protection against UV rays, it is advisable to paint the cured seal.

To ensure better penetration and sealing, you have to let the finish sit for 75 minutes at around 72 degrees Fahrenheit temperature. So you can make a seal and aluminum boat patch absorb the stress brought by shock, vibration, expansion, and contraction.

- Two-part sealer for effective use

- Easily achieves the right ratio of resin and hardener

- Creates waterproof seal

- Sag-resistant for no dripping on holes

- Absorbs stress from movements

- Needs to paint the seal for UV protection

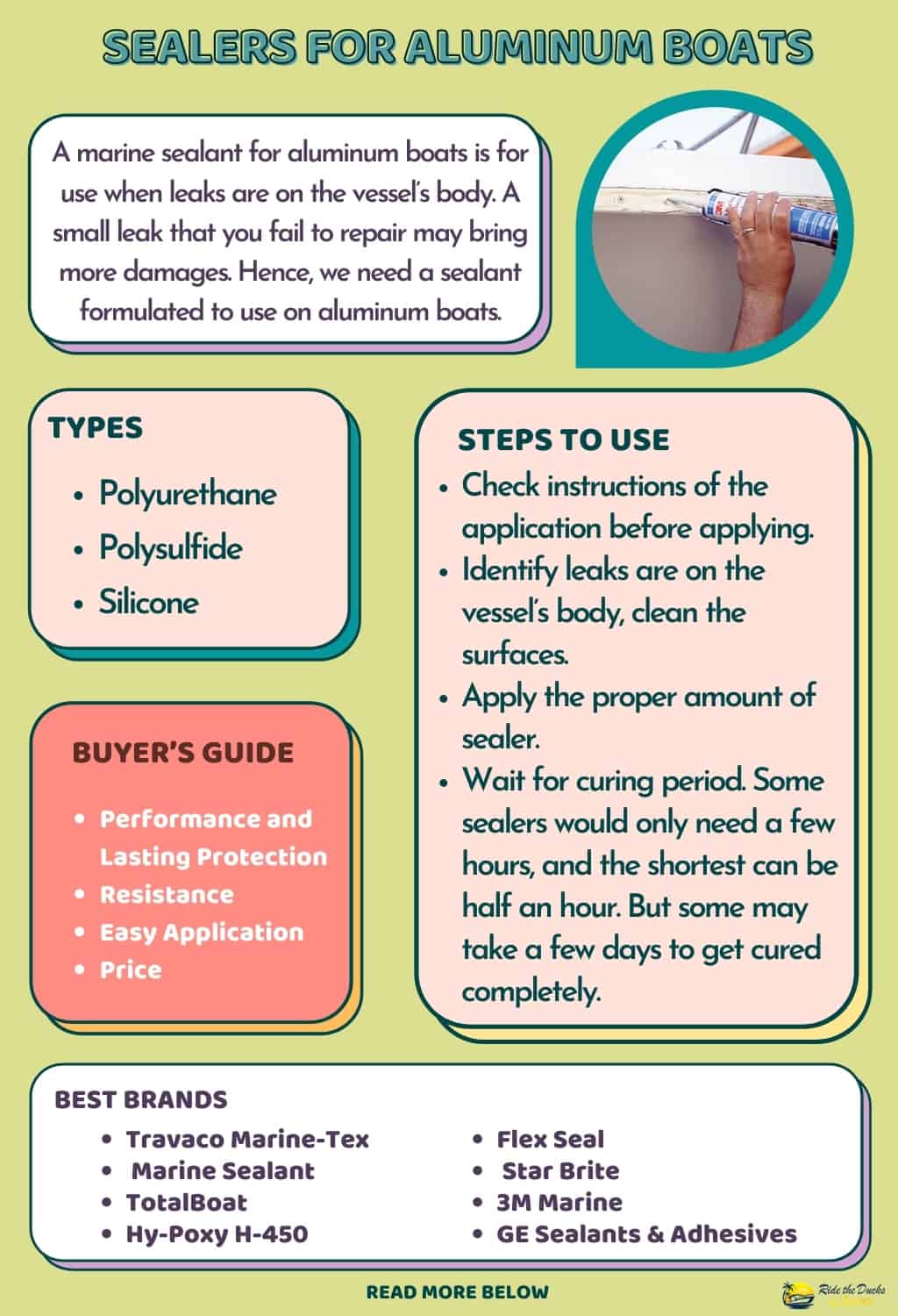

What is Marine Sealant and How Does It Work

A marine sealant for aluminum boats is for use when leaks are on the vessel’s body. A small leak that you fail to repair may bring more damages. Hence, we need a sealant formulated to use on aluminum boats. Also, if you are a first-time user, fret not as the application is a breeze as long as you follow the manufacturer’s instructions.

Seams and rivets are the common areas with leaks. What the marine sealant does is strengthening the areas that require repair. Its penetrating ability also works on molding, decking, and stringers.

Marine sealant can do many things. For instance, it’s resistant to abrasion and impact. It’s a great feature as it prevents corrosion and blistering of fiberglass if you have it on your boat. Its resistance extends to chemicals, water, and potentially damaging environmental elements.

It does repairs excellently, and it can withstand the wear and tear along the way. Curing varies per brand, and after this process, you can paint the surface. Prepare the essential things before you start applying them on your boat.

Curing needs a little time, so you can return to the lake or river with your aluminum boat without waiting for too long.

Types of Sealers of Aluminum Boats

Polyurethane

It is a substance that can establish more adhesion rather than just sealing. It will be practical to have it as it assures you of long-lasting hold. The strength of polyurethane is beneficial for making bonds on hull fittings and deck or hull joints.

This product works well on the aluminum surface but not on a plastic material that is fragile to oil and acid.

Polysulfide

Synthetic rubber sealer is deemed as the most versatile material. A two-part application is usually part of this sealer. You have to understand that these parts are recognized as caulking items. It is not complex to use, and it gradually cures for a sturdy hold.

The two parts of polysulfide stick to different types of surfaces. It implies that you can have it in aluminum, other kinds of metal, wood, and glass. However, this sealer is not suitable for frames, plastic deck fittings, acrylic and polycarbonate windshields.

Silicone

The application is super easy as silicone is elastic. It is also known as resilient to chemicals, and it’s an efficient material when separating things that are not metal. When it comes to adhesion, it is not as robust as the other materials.

You may need to get rid of tough debris, but nothing will stick with it like fresh silicone and paint.

Benefits and Drawbacks of Using Sealant for Aluminum Boats

An aluminum boat allows you to enjoy the water. The quality of the aluminum would be noticeable in just a glance, as well as the issues. This point of view encourages every boat owner to apply the sealant. With cracks and holes, the sealant would fix those issues and provide long term protection.

Hence, you’ll be able to avoid spending more money on necessary repairs. Some sealants would allow you to do the fixing while you’re on board, even with water around you. You can do it right away once you see the issues.

You will only come across drawbacks if you don’t follow the recommended steps of the manufacturer. Some cases are with inadequate drying time, or the mixture is not right. So you’ll end up with an unstable hold, and it suddenly peels off.

Buyer’s Guide

There are many reasons behind the need to get the ultimately effective aluminum boat sealer. You should get it to practice the real deal of the maintenance. It’s also what you need to do for the longevity of the boat. You can’t just choose the right sealant in a snap of a finger.

Here are some factors that you have to ponder onto:

Performance and Lasting Protection

An ideal aluminum boat sealer can provide maximum protection that can last for a long time. The product can make a solid bond and a reliable sealing capability, thus guarantees the optimal performance of the boat.

Some sealers are formulated for many applications. You must choose that one that can adhere to an aluminum surface pretty well.

Resistance

The finish that a sealer can form should be resistant to chemicals, water, and environmental factors. It will be durable if it can surpass damaging elements in the surrounding, especially with weather changes. Chemicals shouldn’t be able to damage it too. Being waterproof is a good indication of its strength.

With its bonding ability and resistance, sealing and shielding will be an absolute provision.

Easy Application

It would help a lot if the application can be easily done. It also contributes to the effectiveness of the sealer.

Price

It will be easy for you to decide when you consider the price as money matters. Not all expensive ones are effective. You’re lucky enough if you see a product that gives you what you need without spending too much. Don’t settle for cheap ones if you can’t attain what your boat needs.

Care and Maintenance

Here are some steps that can guide you for the necessary care and maintenance of aluminum boat sealer:

- Stand by the instructions of the application and some safety measures given by the manufacturer. Always check the label for this before applying.

- The coat of the previous sealer should be removed before getting started. The surface should be clean, and you can use acetone to eliminate tiny bits. You have to let the sealer dry before applying different kinds of coatings like paint and varnish.

- Apply the proper amount of sealer. Don’t be stingy when you apply it on hulls and decks and fastening hardware.

- Curing period varies from product to product. Some sealers would only need a few hours, and the shortest can be half an hour. But some may take a few days to get cured completely. You can count on its robustness when it takes a long time to dry and cure.

Moisture or dew that fills the air can hasten the curing period of sealer made of polyurethane and polysulfide.

- When you are using a mechanical fastener to seal, don’t miss tightening the nuts because it will ensure a watertight bond.

- Seal any leak or crack on your aluminum boat in a well-ventilated place. Prepare all the needed items.

- Manufacturer guidelines are still important when it comes to removing the sealant.

- You can use acetone, kerosene, and mineral spirits when removing spillage, excess, and misapplication. Such an occurrence can’t be avoided. You may also refer to the manufacturer’s instructions when making corrections or removing spillage.

Frequently Asked Questions

Who makes the best sealer for aluminum boats?

The ones who make the top-rated sealer for aluminum boats are Travaco Marine-Tex, Marine Sealant, TotalBoat, Hy-Poxy H-450, Flex Seal, Star Brite, 3M Marine, and GE Sealants & Adhesives.

Does flex seal work on aluminum boats?

Yes, it does. Some products from Flex Seal can adhere to various surfaces, which include aluminum. The exemptions are plastic and rubber. It will bond on either wet or dry surfaces. You will be able to use it even underwater as it can become dry with water around it.

To obtain the best result, put a generous amount of flex seal on the damaged area. Press it firmly for adhesion and to get rid of the water. This step will ensure that it has contact with the surface. Etching can be done to improve adhesion.

Flex seal is ready to use, and there’s no need to add water or other substance. Once the curing is done, it is resistant to mildew, UV rays, and chemicals. Thus, you can rely on the repair made out of it. To make the seal smooth, you can use a trowel, putty knife, and similar tool.

How to fix aluminum boat leaks?

The first thing that you need to do is to check the specific areas with a leak. Fill your aluminum boat with water that reaches the waterline. Start with one end so you won’t distort the shape or the form of the boat. Use a waterproof marker to put markings on the leak.

Clean the leaking area with a brush to remove any debris. Once you’ve tidied it up, you can apply the sealer. It depends on what you have, whether you can apply it directly or mix it first. Anyway, manufacturers provide guidelines, including drying time.

Once it’s dried, you can have a water test. Most of the sealers can be used right away after drying. Some would be fine after you placed it on a leak, even in an emergency.

How do you seal a riveted aluminum boat?

When sealing a riveted aluminum boat, you have to follow the concept of blocking the water to get inside rather than controlling where it goes. You should know that sealing from the inside is not different when you do it outside.

When you use a sealer, it will still seep throughout the shaft of the revit. You can use an epoxy sealer with resin and a hardener. Heat the revit as well as the seam with a propane torch to dry the involved areas. A tool akin to a syringe is used to apply the sealer mixture.

After filling the affected area, heat it with a heat gun to make it set in. Give it enough time to dry. You do this process independently.

You may also do a mechanical repair which should be done by two people. One person needs to hold the hammer hand, and the other would place the rebar. It is applied against the tail of the leaking rivet. Strike the rivet with a hammer to tighten.

Is JB Weld good for aluminum boats?

JB Weld works on any metal surfaces except lead. Hence, it’s effective on aluminum boats. A mechanical fastener can help you out if you want to separate some parts.

This product is ideal for DIY marine and fixing water vessels. It happens as it can create a strong bond on the surface. Just think of its 5020 PSI tensile strength! This sealant is also resistant to chemicals, acid, and petroleum when fully cured.

Its strength is fascinating as it’s consistent whether above or below the water. It can even withstand high temperatures up to 287 degrees Celsius. With its superior performance and quality finish, the product can be suitable for making repairs on aluminum boats. It even presents itself as the strongest bond in the world.

Where can I buy it?

If you want to buy a sealer for aluminum boats in person, you can visit local hardware stores or boating supply shops. Some products are out of stock in these establishments. Online stores offer a wide range of products. But you have to go to a reputable website.

You’ll be able to gain information and knowledge about the products. Then it will be easy for you to choose the right sealer. Access to freebies and promos is also available online. If you get lucky, you will get the best deal.

Conclusion

There are different mixtures and formulations of sealers nowadays. The best sealer for aluminum boats for you will depend on your needs and style.

Some boat owners may regularly need to use their boats. Thus, they would need quick fixing. Some can set the time to fix their boats and can wait for them to completely dry. What matters in these different cases is that the sealer provides a long-lasting repair that can resist the potential harm of environmental elements and weather changes.

I am passionate about water sports and technical fields, so combining both makes me interested in making contents about boat accessories. With my partner, we went on many trips and sports games together, which led us to think about how we can spread our joys and passions to many people.