Different materials are used in making boats and other water vessels. When doing some fixing on a boat, you will be prompted to deal with cement, metal, fiberglass, plastic, or carpentry. In this aspect, you have to specify which substance is appropriate for a specific surface.

You should acknowledge the need to get the best marine epoxy for your boat. Repairs and projects won’t be successful if you don’t use the right one that adheres to the material.

Selecting a marine-grade epoxy is a quest for you, which requires thorough consideration. To save you some time and effort, this review features the different epoxies that you can depend on for your boat’s maintenance and repairs.

J-B Weld 8272

| + Sticks to various materials |

| + Waterproof seal that withstands chemicals |

| + Resilient to high temperature |

Loctite 1919324

| + Convenient application |

| + Gives an off-white finish |

| + Applicable to different materials |

TotalBoat Epoxy Resin Kit

| + Formulated viscosity for wetting fiberglass |

| + A high-strength product that resists moisture |

| + Two types of hardener: slow and fast |

Table of Contents

- Top 12 Marine Epoxy Reviews

- 1. J-B Weld 8272 MarineWeld Epoxy

- 2. Loctite 1919324 Marine Epoxy

- 3. TotalBoat Epoxy Resin Kit

- 4. PC-Products PC-11 Epoxy Adhesive Paste

- 5. TotalBoat High Performance Epoxy Kit

- 6. Better Boat Crystal Clear Resin

- 7. Clearcast 7000 MARINEGUARD 8000

- 8. Brampton Marine Epoxy

- 9. TotalBoat TB-CPEKITHG Epoxy

- 10. PC Products PC-Marine Epoxy Putty

- 11. Pro Marine Supplies Crystal Table Top Epoxy

- 12. WEST SYSTEM 105-A Epoxy Resin Bundle

- What is Marine Epoxy and How Does It Work

- Types of Marine Epoxies

- Benefits and Drawbacks of Using Marine Epoxy

- Buyer’s Guide

- Care and Maintenance

- Frequently Asked Questions

- Conclusion

Top 12 Marine Epoxy Reviews

1. J-B Weld 8272 MarineWeld Epoxy

The dependability and versatility of this marine grade epoxy are its characteristics that I benefit from the most. I don’t have to switch to different products just to meet the demands of various materials. In truth, this one can stick to aluminum, metal, wood, fiberglass, and plastic.

I’m a water sports enthusiast, so this two-part epoxy helps me a lot in maintaining my frequently-used boats. Once you see this product’s outcome, you would agree that it’s a heavy-duty kind that forms a super-strong bond. Also, the repairs that you make will last for an extended period.

Relying on its strength and support never disappoints me. It has a 5020 PSI tensile strength consistency whether you place it above or below the water. I’m also amazed by its resilience towards temperatures up to 550 degrees Fahrenheit.

I was able to finish small or big jobs on my boats and pontoons. The superior adhesion makes the repairs last for years. As you can expect from a marine epoxy, the finish is waterproof and can withstand acid, petroleum, and chemicals.

Even though epoxy is for repairs and restoration, you still have the liberty to do what you like after the curing process. I usually sand the finish, and I sometimes do some drilling. You also have the option to fill, tap, or mold the finish.

- Sticks to various materials: aluminum, metal, wood, fiberglass, & plastic

- Heavy-duty epoxy forming a strong and long-lasting bond

- A consistent 520 PSI tensile strength, above and below waterline

- Resilient to high temperature (up to 550°F)

- Waterproof seal that withstands chemicals

- Requires mixing the components

- Emits a bit of odor while curing (within 16 to 24 hours)

2. Loctite 1919324 Marine Epoxy

Loctite has been producing high-quality marine sealants and adhesive for five decades. You won’t be disappointed with their products, like this epoxy that gives an off-white finish. I can say that the manufacturer prioritizes convenience in making it.

Application is not as complicated as other brands because it’s encased in a syringe. This packaging allows you to dispense the necessary amount and avoid wasting it. Mixing the equal quantities of resin and hardener creates a rigid, strong bond.

Besides, this Loctite marine epoxy can be in a wide range of applications, as once cured, it doesn’t crack even if you drill it. So you can fix some parts even with hinges. The other reason is its adhesion to various surfaces made of metal, glass, rigid plastic, wood, and more.

You will love how you can use it in times of emergency as this substance cures underwater. But let it dry a little before applying, as it’s a bit loose at first. You can skip draining out the water. I’ve used it on fiberglass and rubber skeg on my boat and on leaking pipes too.

Once it’s set, the finish doesn’t shrink but instead bone dry, lasting for many years. One-time application is sufficient in fixing a specific area, and I don’t need to reapply until now. Notably, the durability of this epoxy shows how it is immensely resistant to solvent and water.

- Gives an off-white finish for new-looking boat surfaces

- Convenient application with a syringe tube

- Creates a rigid yet flexible bond that allows drilling afterward

- Applicable to different materials: metal, glass, rigid plastic, wood, etc

- Cures underwater and lasts for a long time with one application

- Might be missing tube cap due to shipping

3. TotalBoat Epoxy Resin Kit

The convenience of this TotalBoat kit is what I need for maintaining my water vessels and tools. It’s composed of resin, two types of hardener, mixing tools, and measuring cups. You can start the application with everything provided.

The viscosity of this epoxy is formulated for wetting fiberglass surfaces as well as reinforcing fabrics. Bare steel, etched aluminum, and wood can benefit from this kit. Sad to say, it’s not a marine epoxy paint fiberglass. Clear coating is not in the scope of its abilities.

Since you can make a thin film out of this epoxy, coating, laminating, and layups for composite parts are the things that you can accomplish with it. I once used it for fixing a delaminated deck. Reinstalling bulkheads is another job that I and this substance carried out.

You can choose between two options of hardeners available: ‘slow’ and ‘fast’. The slow hardener creates a plastic solid with an amber color. High strength and resistance to moisture are the highlights of its capabilities. Sanding or shaping are the processes that you can do with it.

The pot life of a fast hardener only takes 12 minutes. When you combine it with a filler, strength in bonding, filleting, and fairing is established. This function only proves the credibility of this epoxy.

- Formulated viscosity for wetting fiberglass

- Ideal for bare steel, etched aluminum, and wood

- Creates a thin film for successful coating and laminating

- Two types of hardener: slow and fast

- A high-strength product that resists moisture

- Available in one quart, a gallon, or 5.45 gallon for different needs

- Not ideal for clear coating

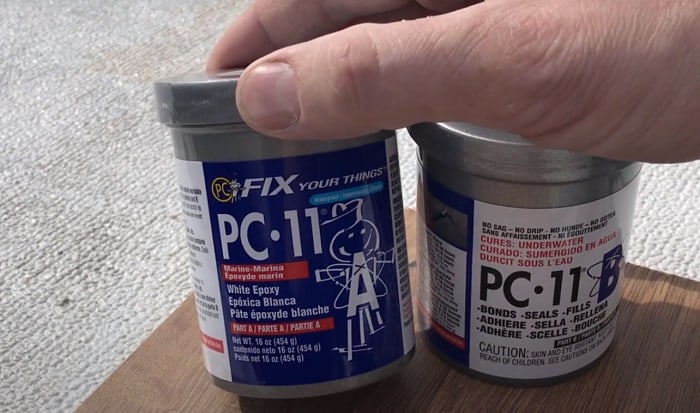

4. PC-Products PC-11 Epoxy Adhesive Paste

Due to the consistency of this PC-Products epoxy, the outcome would be satisfactory. Being designated in marine use, it can adhere to dry, wet, and even submerged parts or areas.

I was able to fix even the thinnest damage, like a hairline crack. I also used it to make a galvanized tank for my turtles with one application. Such use proves that this epoxy can be in charge of the smallest job.

Just like what I want with marine epoxy, it can be an incredible filler. It can patch up holes, voids, castings, patterns, and welds, meaning you can cover pipe leaks at home with this epoxy. I’ve also discovered that it’s safe for various tanks that hold water, oil, or gas.

It has a thick texture that makes it effective, but it requires a lot of work when you need a huge amount for a big task. You can ease out stirring by using a spatula and a spinning tool. I like it thick as it doesn’t get saggy when you cover some holes. The tensile hold is superb too!

The great thing about using it on large jobs is you have enough time to have some changes and repositions. Exclusivity is not a thing for this epoxy as it can handle different materials like fiberglass, glass, stone, concrete, rubber, tile, wood, metal, and the list goes on.

Another ability that I admire about this epoxy is being able to adapt to different temperatures. In detail, its indoor formula can handle 35 to 115 °F, while the outdoor one ranges from -20 to 200 °F.

- Marine epoxy for sealing submerged parts

- Fixes hair crack damages with ease

- An incredible filler for holes, voids, castings, patterns, and welds

- Adheres to any surface and material: fiberglass, glass, stone, concrete, rubber, etc

- Adapts to different temperatures ( 35 to 115 °F & -20 to 200 °F)

- Resists impact and thermal shock

- Stirring a huge amount is a lot of work because of its thick texture

5. TotalBoat High Performance Epoxy Kit

What you can get from this TotalBoat High-Performance epoxy kit is resin with low viscosity and a hardener that doesn’t stain. The clear coating is what makes me love this item more. I can consider it a marine grade epoxy paint as it can blend well with thickeners, coloring agents, and thinners.

Two parts of resin and one part hardener are the recommended ratio to achieve an excellent result. The package also includes mixing cups made of plastic and mixing sticks. Unfortunately, dispensing pumps are not included, so I had to buy some to avoid messy applications.

There are three types of hardeners to meet every user’s demands. The fast hardener means having the shortest working time and the quickest to cure. The medium type is suitable for most applications, while the slow one is the total opposite of the fast hardener.

The hardener is the main reason why this product can be utilized in a wide array of applications. Repairs on my boat are established well, and it makes me feel at ease. It also takes part in boat building. Every user can engage in different projects because of its versatility.

- Comes with low-viscosity resin and a hardener

- Blend well with thickeners, coloring agents, and thinners

- Available three types of hardener with different working and curing time

- Straightforward application without blush removal

- Emits no toxic odor while curing quickly

- Dispensing pumps not included in the kit

6. Better Boat Crystal Clear Resin

If you want some gloss on the finish of epoxy, this is the right product for you. You will be in love with the smooth, crystal clear finish of this item. It was my reaction when I saw the result for the first time. Ideas of various usage also popped in my head.

The first project that I did with this product is fixing a 30-year old wooden boat. I sanded the parts first before applying this blend of resin and hardener (half gallon each). The glossy finish brought back the luster of the boat that was lost.

The glossy coating is great for encapsulation, woodwork, tabletops, and bars. It plays a big role in artworks too. Some folks in my neighborhood customized tabletops and kitchen counters with this epoxy. They were able to create unique designs out of it.

Expect a thick substance, so you have to place the bottles in warm water before using them. I think it is made for impatient people like me as it only takes some minutes to set in and start curing. In this case, you have to swiftly move during application to avoid getting caught up.

Fifteen to twenty minutes are enough for the substance to set in. The epoxy doesn’t just come together for the glossy effect but with heat resistance as well. It can withstand temperatures up to 120 degrees Celsius.

- Offers a smooth, crystal clear finish

- Great for restoring old, wooden boats

- Can be used in artwork

- Heat-resistant up to 20 degrees Celsius

- Has coverage chart guide for correct purchase

- Requires placing the bottles in warm water before using

- Swift movements are needed during the application

7. Clearcast 7000 MARINEGUARD 8000

Finding out about this product makes me realize that we do not necessarily spend a lot of money to get a high-quality item. Although this product’s combination of resin and hardener is not similar to that of leading brands, it suffices in restoring boats.

This marine epoxy usually takes half an to get tacky and 7 to 8 hours to cure. Being patient within this duration will give you a rigid and tough finish. I fixed the hull with it, and I can testify how it repels water. Moreover, it remains defiant against salt, wind, corrosion, acid, and other harmful chemicals.

Ease of use results in a convenient application despite the need for a 2:1 mixture. In exchange for time and effort, you get to fix different materials with this 2 part epoxy paint for boats.

Yes, you can apply it on different surfaces like fiberglass, concrete, and metal. It’s also involved in civil and industrial engineering. In truth, many use this epoxy on skylights of metal buildings and assembling boat parts. Since it’s formulated for marine use, weatherproofing is another thing that it does well.

I got creative with this marine epoxy and discovered that it could be a filler too. But you need to mix it with some ingredients such as carbon powder, silica, or sawdust. Then you can work on knots and screw holes.

- An affordable product that delivers an effective formula

- Leaves a rigid and tough finish

- Resists water and remains defiant against harmful elements

- Ideal for use on fiberglass, concrete, and metal

- Has incredible wet-out properties for smooth application and full coverage

- Have to follow the 2:1 ratio with ingredients: carbon powder, silica, or sawdust

8. Brampton Marine Epoxy

This Brampton Marine epoxy has tons of abilities relevant to marine use. I can say that it excels among numbers of epoxies and superglues for underwater areas.

What’s fascinating about it is being able to stick with almost every surface. Whether you’re working on galvanized steel, graphite, fiberglass, PVC, and other existing materials, you will attain the all-weather bond from this epoxy. Cold, heat, and humidity can’t take down its grip.

More importantly, this marine-grade formulation of this marine epoxy is outstanding as it allows you to work underwater. Whether you’re in freshwater or saltwater, it will work with no doubt.

Even though some parts are soaked up with water, you can still mend them. It happens as this epoxy can resist impact along with its tensile strength. Conventional epoxies usually don’t have this quality.

I also learned that it could resist the deteriorating impact of solvents, petroleums, and other chemicals. That is why this product is best for repairing vehicles such as boats, surfboards, jet skis, and other water equipment.

Surprisingly, the application is a piece of cake, as no tool is required. You can quickly and precisely add this epoxy to the leak, thanks to its easy-squeeze bottle. Dispensing the necessary amount won’t trouble even first-timers. I avoided making a mess on my first application, and I’m sure you’ll do too.

- Sticks to any surface: galvanized steel, graphite, fiberglass, PVC, etc

- Creates weatherproof bond for vehicles

- Marine epoxy that works underwater with great tensile strength

- Resistant to impact and chemicals

- In easy-squeeze bottles for hassle-free application

- Has a bit of smell (tip: apply in a ventilated area)

9. TotalBoat TB-CPEKITHG Epoxy

Since I own a wooden boat, I need a clear marine epoxy that doesn’t alter the wood’s natural color. This creation from TotalBoat indeed matches my preference and need.

Upon seeing the result of this epoxy, it reminds me of a newly painted wall due to the excellence of the finish. As this marine-grade epoxy can penetrate the wooden surface, even a decade old wooden boat was restored by it. I was able to make mine look good as new without spending a lot of money.

With its low viscosity resin formula, the product sticks well on both hardwoods and softwoods. You can utilize such a seal for the dry-rot method to restore all wooden parts of your boat. It works wonders on numerous materials often used to construct marine vessels: maple, oak, cedar, pine, etc.

Sealing with this product means protecting the wood from moisture intrusion, fungus, mold, and mildew growth. Hence, wood rot is not something that you have to worry about anymore.

Concerns about the weather should be disregarded as two formulas are available. For 65 to 90 degrees Fahrenheit temperature, use the regular one. The other formula is for cold weather, which shouldn’t exceed 65 degrees Fahrenheit. Whichever part of the world you are in, feel free to make good use of this solution.

In terms of application, cleaning the wood first is essential. Make sure the surface is dry before application to avoid the formation of bubbles. Rest assured that the treatment is simple, and no annoying fumes can be detected.

- Offers excellent finish similar to a newly painted surface

- Low viscosity works well on both hardwoods and softwoods

- Forms protection against moisture intrusion, fungus, mold, and mildew growth

- Two formulas for below 65 and from 65 to 90 degrees Fahrenheit

- Comes in different sizes: a quart, pint, or a gallon

- Formation of bubbles when the wood is not dry before application

All in all, this epoxy can help you with this matter with its low viscosity resin and versatile uses on different wooden surfaces.

10. PC Products PC-Marine Epoxy Putty

Making a quick fix on either a dry or wet surface is what you can do with this PC-Marine epoxy. Sounds good, right? This epoxy comes for the rescue in times of emergency.

The discovery of its reliability happened when I fixed an abrasion on my aluminum boat while I’m on a lake. I’m impressed with how it can fulfill rapid repairs despite parts being submerged underwater. The substance will stick as long as the surface is clean. Give it twenty to thirty minutes to work; then, an hour is enough for complete curing.

This product is a two-part marine epoxy paint for steel that bears a white color, and it adheres to many materials. Don’t hesitate to use it on different metals, fiberglass, plastic, PVC, wood, grout, concrete, and gunite. No matter what your boat is made of, this epoxy will stick.

Repairs made with this epoxy spread out to many things due to its flexibility. It’s useful on aquariums, pools, tubs, and plumbings. Believe it or not, a friend used it to fix the shell of a snail that resides inside her aquarium. The creature is now thriving after the incident.

- Offers quick and emergency repairs within an hour

- Marine epoxy for dry and wet surfaces

- Adheres to many materials: metals, fiberglass, plastic, PVC, grout, gunite, etc

- Simple application without tools to mix

- Doesn’t drip or sag

- Withstands a wide range of temperatures ( -20 to 250 °F)

- The submerged part should be clean for application

11. Pro Marine Supplies Crystal Table Top Epoxy

I’ve been getting a lot of compliments about my wooden deck. Some friends even asked me how to do the same process on their boats. So, I spread some good words about this Pro Marine epoxy, which creates smooth surfaces like glass.

Once you see the result, you won’t think twice about using this on your wooden deck, interiors, and other marine parts. The durable and high-gloss finish comes together on every available material.

The versatility of this substance makes it useful in artworks and home projects. Toughness and durability make a reliable finish. Since it’s food-safe, you won’t hesitate to place edibles over the glossy surface. No need to worry about scratches and harsh sunlight as it’s highly resistant to those things.

Doing the proper steps will give you a flawless finish. That’s why I’m very attentive during the application, as steps are crucial. You can start with a temperature of 75 to 85 degrees Celsius and the correct mixing procedure. Then mix it in a bucket or a circular container.

An electric mixer is not ideal for blending everything well as you want to achieve a bubble-free surface. The formula is 1:1 self-leveling, so it’s best to pour more during application. Take note that the hardener tends to settle on the top as a thin layer. Push it down while you stir the mixture.

- Creates solid, high gloss finish

- Tough and durable for long-lasting shine

- Applicable to various materials, thus ideal for artworks and home projects

- Comes with a food-safe formula

- Resistant to scratches and sun rays

- Detailed instructions are included

- Application procedures are crucial to achieving the desired result

12. WEST SYSTEM 105-A Epoxy Resin Bundle

What I love about this WEST SYSTEM epoxy is its fantastic adhesion. It’s more versatile than many competing brands, and it’s wonderful being a shelf-stable.

This product adheres to metal, concrete, wood, and fiberglass, proving its application versatility. It’s dependable on repairing cracks or chips and holes on boats, pontoons, jet skis, and other water vessels. I made it into a filler, so irregular cracks and even a large void are no longer visible on my boat.

The robust and hard finish from this epoxy can be sanded when it’s applied to wood. Once, I created a smooth surface for the boat surface, then did a bit of dying to even out the area’s color.

Just like other brands, this West System epoxy has two parts, which are resin and hardener. Yet, you must know its exothermic nature. Only use a container that can withstand heat during the mixing process. Fret not, as the application is not as complicated as it may seem.

Pumps are included in each purchase, and I’m thankful for this part. I can avoid spillage or wasting some substance. They also make the mixture easier as dispensing the epoxy parts is done by pumping. I won’t be inclined to take out extra quantities that would only be wasted.

- Shelf-stable product with excellent adhesion

- Adheres to metal, concrete, wood, and fiberglass surfaces

- Works as a filler to seal small cracks and holes

- Included pump for straight-forward mixing and applying

- Cures and forms strong finish within a day

- The exothermic nature requires a container able to withstand heat

I’m no longer intimidated by how big or thick the cracks found on my boat. Make this marine epoxy as a filler, and you’re good to go.

What is Marine Epoxy and How Does It Work

A marine epoxy is usually a combination of resin and hardener. With this blend, you can work on the hull and even underwater pipes. This item works as a gap filler and beneficial for reconstruction. The finish brought out by epoxy is reliable and can be sanded, painted, and drilled.

Marine epoxy is naturally waterproof to indemnify the consequences of frequent water exposure. The finish should be tough and reliable, so it can tolerate harsh weather conditions.

Types of Marine Epoxies

Marine epoxies are determined based on the resin added into its formula. When talking about marine epoxy types, marine epoxy types are sorted out based on the resin it contains.

Casting Resin

The role of this resin is casting molds. You will notice that it’s relatively thinner than the other types. Thus, it is ideal for different applications with variations in the mixing ratio. Patience is required when working with it as it needs a long curing time.

The main uses are enclosing some things or parts, lamination of surfaces, and filling in spaces or gaps on wood.

Coating Resin

The name shows how this resin works. Yes, it coats surfaces even in a vast scope. It has a texture thicker than the casting resin, and it achieves complete curing quicker as well. Mixing comes with ease when you go for its application.

This epoxy is also capable of sealing and bonding objects. Many apply it on the decks and surfboards, and the product does magic on furniture pieces too.

UV Resistant and Marine Grade Epoxy Resin

Since this substance resists the harsh UV rays, yellowing is prevented. So the nice appearance of the finish would last for a long time. The efficacy is useful in boat building and fiberglass manufacturing. It has a reliable adhesion too. Thus, sealing a small area is what it does best.

Polyester Resin

The content of this substance can be various polyester or unsaturated synthetic ones. Polyester resin contributes a lot to the composite industry. It is also found in different kinds of projects. The ability of this resin is compliant with the needs of boat building and plastic repairs.

Due to its weather-resistant property, it’s one of the important things used in outdoor construction projects. There’s no doubt that you can use it in fixing pools and jacuzzis.

Polyurethane Resin

This resin is composed of plastic and is considered a synthetic resin, coming with great versatility. What would impress you about this substance is how pliable it is. It can be modified to form other materials.

Polyurethane is usually in liquid form. Pouring it into molds will allow this resin to make some shapes. Customization with the final product can be done with fillers or additives.

It’s used for mold casting and casting tires. Floor coating is one of its jobs. The encapsulating ability of this substance is tremendous as it’s even used on electronic parts.

Marine Epoxy Paint

This epoxy is formulated to comply with exterior usage. Hence, it’s more on the beautification side. Once it’s settled on the surface, it can resist water and protects against extreme conditions.

Before applying the epoxy paint, you have to clean or sand the surface. Then, some cases would need a primer before the paint.

Benefits and Drawbacks of Using Marine Epoxy

Benefits of using marine epoxy:

- Aside from taking care of personal boats or water vessels, it’s also utilized at home, in automobiles, and in other industries. Since it’s a repair agent, it’s deemed very helpful in building and reconstruction.

- Wooden surfaces get protected because of their penetrating ability. The protective coating that it forms can impede moisture intrusion, so the wood can remain in good condition.

- Damages like rotting can be easily defeated by marine epoxy. It can get rid of instant deterioration too.

However:

- Most marine epoxies would tend to have an odor, and you have to stand it during application.

- If proper procedures are not practiced, you may end up with a finish filled with bubbles. A lumpy surface can be another issue. Epoxies are self-leveling, so drips should be an immediate concern.

Buyer’s Guide

The epoxy that you’ve chosen should be appropriate for the repairs or projects that you’re working on. And don’t miss checking the shelf life or the expiration date.

If you need something for an emergency, get an epoxy that can be a filler. Yet, do not start the process if you haven’t read the manufacturer guide. Take note of the required time for curing. Other requirements include temperature and humidity.

Protective gear should be worn when applying marine epoxy. Have your goggles and gloves ready before application

Care and Maintenance

You can use brush, roller, and mixing tools to apply marine epoxy properly. In some cases, you may not need to sand the surface. You can pour the epoxy right away then sand it once cured. This process makes the finish low-maintenance.

The result of marine epoxy is deemed as tough and flexible. So it’s another reason that won’t require strict maintenance. The coating is made won’t be degraded by saltwater, oil, gasoline, and other chemicals. Various materials get protected by it. So it doesn’t need much care and maintenance.

The coating for timber or other kinds of wood is better if you make it into two applications. It’s fine to use a brush or a roller to secure a tough coat. The seal that it creates endures despite the effects of water and outdoor elements. This ability is not found in primers, wood preservatives, and even paint.

Frequently Asked Questions

Who makes the top-rated marine epoxy?

The ones who make the best marine epoxy are J-B Weld, TotalBoat, Loctite, Clearcast, PC-Products, Better Boat, Brampton, Pro Marine Supplies, and WEST SYSTEM.

Which is better epoxy or polyester resin?

An epoxy resin is also used in boat building and DIY projects. It has water-resistant properties, so any material gets protected. This substance is referred to as the marine grade or something for art and tabletop. Users applaud it for its remarkable toughness, versatility, and flexibility.

On the other hand, polyester resin is more affordable than epoxy resin. It’s flexible as it allows you to do some designs by controlling the amount of hardener. This means that you have to attend to the measurement of the mixture to get the ideal result.

Unlike epoxy, polyester can’t stick with glass, metal, or other smooth surfaces. An unpleasant smell also comes from it. This synthetic resin is not as water-resistant and durable as epoxy. Deterioration can happen as there’s a high chance of shrinkage to its seal done by polyester.

How thick can I pour epoxy?

It is advisable to consider the proper thickness when applying epoxy as it triggers the increase of heat. The incorrect application will eventually result in excessive bubbles, and some cracks will appear on the finish.

The thickness of the epoxy depends on the size of the working area and the type of application. Marine epoxies can be in different forms like being a coat, mold, filler, and paint. The manufacturer’s instruction is another factor that you have to consider.

So it’s always best to check labels and manuals first. Some would require you 1/8-inch thickness. Some epoxies should be applied in an inch for larger application and 2-inch for molds.

How to apply marine epoxy?

Some cases would not require sanding. But still, it’s good if you roughen the area you’re working on with premium quality sandpaper. Carefully remove dirt, dust, and grease to ensure that you get rid of every bit of unwanted particles.

The common thing about marine epoxy is combining resin and hardener before the application. Manufacturers give you information about their products so you won’t go astray from the right procedures.

See to it that the two parts blended well to obtain an excellent finish. Add a bit of adhesive when you need to bond some parts. Gingerly squeeze the area for a solid hold.

Brands have different formulations so does the time that the epoxy fully cures. Excess epoxy found on the edges or the surrounding of your working area is inevitable. Make sure to remove it so it won’t proceed to cure.

How long does marine epoxy last?

The coating or the mold that a marine epoxy makes can last for years. This product has a lasting formula, so you can count on it.

Is marine epoxy waterproof, flexible?

Once you see the indication of marine-grade in items, the waterproof feature is elaborated. Some epoxies need to be cured to become waterproof.

You can find ones with a more advanced formulation that can cure even with the water around the damaged area. This attribute is what you need in times of emergency.

Being flexible comes in being able to adhere to different materials and surfaces. Marine epoxy has ‘pot life’, which is the period open for modifications. The substance doesn’t dry instantly, and you have some minutes to get the proper mold.

Where can I buy?

Marine epoxy resin suppliers are everywhere, so it’s not hard to find and buy it. Buying one in home depot branches or local stores gives you a chance to check the product in person.

You may opt for online shopping. Deliveries are reliable, and shipping fees sometimes come for free. But be careful with the websites that you access. Make sure it’s legitimate.

How to remove marine epoxy?

You’re well aware that a marine epoxy is formulated for long-lasting adhesion. Making a mess may happen, especially for beginners. No one wants to get stuck with its remnants. So you have to learn how to clean up the right way.

So, prepare for an aggressive technique. To soften the epoxy, you can use an adhesive remover, paint thinner, or denatured alcohol. Dip a cloth on one of the solutions, then rub it on the epoxy.

Conclusion

What will lead you to discover the best marine epoxy is its formula. It will be the basis of whether the epoxy is suitable for repairs, taking care of leaks, reconstruction, or building. You may also look for special features like being able to cure underwater and a whole lot more.

I am passionate about water sports and technical fields, so combining both makes me interested in making contents about boat accessories. With my partner, we went on many trips and sports games together, which led us to think about how we can spread our joys and passions to many people.