You may find yourself in hard times of searching for the best marine sealant. As a boat owner, you know that it’s an essential thing as there might be instances that you need to cover up cracks, leaks, or dents. With a multitude of options in the market, finding the right sealant can be a challenge.

A sealant or caulk should be marine-grade and top quality. So you would know if the formulated solution can work well with your boat materials and conditions.

This review has narrowed down the best ones you can get, considering each product’s pros and cons. Then, you analyze some aspects to find the most suitable one in providing your boat’s needs. Read on to explore these incredible options.

3M 5200FC

| + Polyurethane polymer material |

| + Ideal for gap filling |

| + Creates a watertight seal |

Better Boat Sealant

| + Waterproof |

| + Effective use above or below the waterline |

| + Flexible after curing |

Loctite Adhesive Sealant

| + Formulated for deck fittings |

| + Withstands both salt and freshwater |

| + No solvent used |

Table of Contents

- Top 12 Marine Sealant Reviews

- 1. 3M Marine Adhesive Sealant 5200FC

- 2. Better Boat Marine Grade Sealant

- 3. Loctite PL Marine Fast Cure Adhesive Sealant

- 4. 3M Marine Adhesive Sealant 5200

- 5. Star Brite Marine Silicone Sealant Clear

- 6. Dap 00694 Silicone Rubber Auto/Marine Sealant

- 7. 3M Marine Adhesive Sealant 4200

- 8. Sikaflex-291 Adhesive and Sealant

- 9. Travaco RM330K Gluvit Epoxy Sealer

- 10. 3M Marine Adhesive Sealant 4000 UV

- 11. Gorilla 100% Silicone Sealant Caulk

- 12. Boat Life Sealant Lifeseal Tube

- What is Marine Sealant and How Does It Work

- Types of Marine Sealants

- Benefits and Drawbacks of Using Marine Sealants

- Buyer’s Guide

- Care and Maintenance

- Frequently Asked Questions

- Conclusion

Top 12 Marine Sealant Reviews

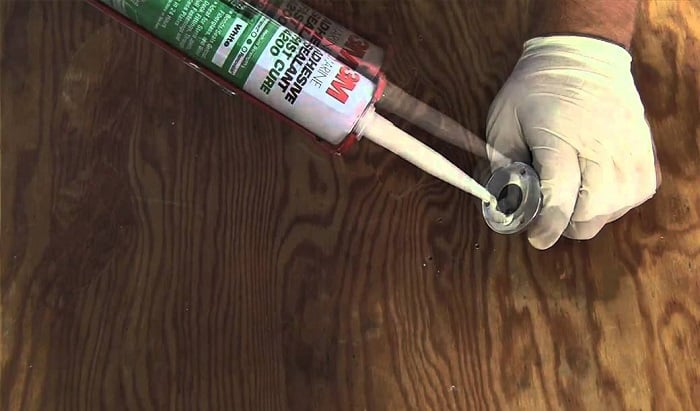

1. 3M Marine Adhesive Sealant 5200FC

When fixing cracks and holes, you have to ensure that your chosen agent will stay for a decent period. Thus, marine sealant for your boat should have the ability to form a permanent bond. Luckily, it is something that this 3M marine sealant below the waterline can promise.

You can use this versatile sealant on aluminum, wood, and fiberglass surfaces on your boat. Such a product with a reliable bond is an amazing option to fix hull and deck seams, portholes, deck fittings, and deck housing. In truth, I once used it to repair some cracks on the hull and stem joints, and achieved a satisfying result.

I imagine it would be amazing to have a boat made of this sealant. I know I sound foolish, but the strong bonds made by polyurethane polymer are rigid and flexible. It can stand the wear and tear when your boat is on the waters. Swelling, vibration, shock, or shrinking can’t deduce its strength.

3M 5200 is formulated as a fast cure for gap-filling and moisture curing. It’s tack-free within an hour or two after application. You have to give it 48 hours for curing and to achieve a strong bond.

I love its watertight seal, and you won’t worry that water won’t get into the areas where you did some fixing. It’s great that you can buy it in a cartridge or sausage pack so you can get the right amount to fulfill your boat’s need for some repair.

- Forms a permanent bond due to polyurethane polymer material

- Uses on aluminum, wood, and fiberglass surfaces

- Movements can’t deduce their strength

- Ideal for gap filling and moisture curing

- Creates a watertight seal

- Require using gloves during application

2. Better Boat Marine Grade Sealant

The Better Boat marine sealant below waterline is widely used by boat owners due to its strength and excellent adhesion. In my experience, the product is reliable in blocking leaks and repairing seams.

Due to its waterproof function, this sealant works wonders in sealing wind-shields, ports, and leaks on various boats. Being a marine sealant that delivers waterproof adhesion, it works on several materials. It permanently bonds aluminum, gel coat, plastic, metal, fiberglass, glass, wood, and ceramic.

I also used it on some hardware. Some people fix something in pools and aquariums using this sealant. It remains effective whether the seal is above or below the waterline because of the proven wide application.

Once the seal is cured, it forms a permanent bond with enough strength and flexibility to maintain our boat in good conditions when traveling or unused. In detail, the agent won’t compromise its strength under harsh weather conditions and movements. You will be impressed with how it can expand, contract, bend, and twist, meaning shocks and vibration can’t alter its efficacy. So I don’t worry when my boat is sailing over fast current or rough water.

I love how it cures quickly, but you have to sand it even though it turns out into a white seal. Do it to match the color of the surface where the application occurs. This part shows that it has potential for cosmetic repairs.

- Permanently bonds aluminum, gel coat, plastic, metal, fiberglass, wood, ceramic

- Waterproof sealant for reparation of boats

- Effective use above or below the waterline

- Flexible after curing, as it can expand, contract, bend, and twist

- Withstand the surrounding elements

- Requires sanding and painting to match its surrounding surface

3. Loctite PL Marine Fast Cure Adhesive Sealant

Are you looking for a marine adhesive sealant that can help you with deck fittings and through-hull fastening? If so, this sealant is for you. When it comes to adhesion, you won’t be disappointed. I can testify to its reliability when used as an above or below waterline sealant.

Based on my experience, this is one of the boat sealants that can create a firm, watertight bond. So the repairs stay in place due to the moisture cure polyether formula of this product. I also used it when fixing some leaks on the PVC pipe.

I don’t question the strength of its bond as it’s hard to remove. It’s a feature that you would appreciate from a marine sealant. That’s why I wear long sleeves and gloves every time I use it. With its strength, you can get some waxing. I need to keep my hair away from it.

Curing sets and stabilizes the seal, as the process acts quickly in a matter of 24 hours. The fully cured seal can withstand both freshwater and saltwater. I can say that this sealant’s effect is also flexible.

I’m impressed that there’s no unnecessary solvent in its formula. Thus, the repairs won’t shrink, form bubbles on damp areas, or discolor under the sun. The seal will surely last long as it can withstand both dry and wet surroundings.

- Formulated for deck fittings and through-hull fastening

- Moisture cure polyether formula creates a firm and watertight bond

- Withstands both salt and freshwater

- No solvent used, thus avoid bubble formation and discoloration

- Available in a 3-ounce squeeze tube and 0.1-ounce cartridge

- Need to wear long sleeves and gloves during application

4. 3M Marine Adhesive Sealant 5200

Professionals use this marine calking item, so I followed the hype. I’m delighted I chose this among the numerous sealants in the market. Who won’t be pleased with the long-lasting formula of this sealant? It makes me avoid spending a lot of repairs as my boat continues to be in optimum performance.

This sealant is composed of polyurethane polymer, a material known for its resistance to saltwater and weather’s damaging effects. Thus, the seal that it creates can last long, preventing your boat from frequent repair.

I love the permanent bond this sealant creates, as it doesn’t only adhere to the interiors but also works as an underwater caulk. Application is effective in areas that sunlight can’t reach. My cousin even uses it to fix some flaws in his RV.

After quite some time, I observe that such a flexible seal does not mind significant movements. It clings on the surface despite any vibration and shock. Notably, this function applies to different surfaces like wood, glass, fiberglass, metals, and painted ones.

Even as time goes by, the seal won’t crack or peel. Application is a breeze as it’s ready to use with no mixing needed. You should also know that its full curing requires 5 to 7 days to ensure a permanent bond. But it’s dry to the touch the following day, and the handling strength is established in 48 hours.

- Has long-lasting formula

- Resists salt water and weathering

- Can make seal underwater and above waterlone

- Adheres to different surfaces: wood, fiberglass, metals, and painted ones

- Won’t crack or peel despite boat movements

- Easy application without mixing

- Requires placing in the freezer after use to avoid hardening the sealant

5. Star Brite Marine Silicone Sealant Clear

This quality marine silicone sealant from Start Brite has many things to offer when fixing your boat. First, you should know that it can bond to different surfaces like metal, glass, fiberglass, wood, and some kinds of plastic.

Whether you need to work on an aluminum tube or close holes on the footrest slide mechanism of a kayak, you can count on this sealant. It applies to almost every vehicle as it forms a bond that stays rigid, even exposed to water or not.

What you need to know about silicone sealant is how you can easily remove it. But it doesn’t falter when exposed to sunlight, solvent, some chemicals, and changing weather conditions.

Remarkably, this silicone sealant is affordable, yet it offers excellent results as the high-priced agents. Plus, you can pick the color that can blend well with the vessel’s color, among black, white, and clear.

In terms of application, it’s tack-free and dry in an hour or less. You don’t have to wait for days as this sealant only requires 24 hours for complete curing. Give it time to set up a waterproof seal to ensure that the repairs that you make won’t shrink, crack, and discolor through time.

- Bond with different surfaces, even plastics

- Creates an airtight and waterproof seal

- No shrinking, cracking, and discoloring

- Comes with different colors to blend with vehicles

- An affordable product with high quality

- Tack-free application and quick drying

- Be cautious when applying as the tube may burst when bent too hard

6. Dap 00694 Silicone Rubber Auto/Marine Sealant

The formulation of this silicone sealant makes it ideal for use as a marine-grade caulk. Thus, it should be in every boat onwer’s tool pack for maintenance and occasional repairs. Other than that, this product is applicable to fix automotive parts, making it popular among DIY-ers.

I can say that it’s heavy-duty silicone rubber with consistent adhesion. More importantly, the dried seal is waterproof and weatherproof, which makes it perfect for marine use. Rest assured that it does not peel off unexpectedly even after prolonged exposure to water.

I’m amazed at how it can bind two pieces of glass and rubber and put plastic together. I once used it to seal cracks on my coffee table made of glass. It’s also useful on tubs, windows, windshields, and some do-it-yourself projects.

Besides its incredible strength, the seal is flexible as well. It can withstand movements and expansion while the boat goes through strong currents. To be honest, this seal stayed on my boat for the longest time, and it hasn’t shown signs of shrinking and cracking.

- Heavy-duty agent for caulking marine vehicles

- Waterproof and weatherproof seal

- Withstands movements and expansion

- Guarantees no shrinking and cracking over time

- Tightens the cap to prevent the substance from hardening

7. 3M Marine Adhesive Sealant 4200

When it comes to marine caulking sealant, polyurethane is a tough material that stands firm against surrounding elements. As it is found in this sealant, I decided to get it. After seeing the results, I know I made the right choice, so I would like to share a couple of wonderful things about it.

This marine sealant creates a strong bond on surfaces like wood, aluminum, fiberglass, and gel coat. The toughness of its seal counters the damages caused by water and different weather conditions. There’s flexibility, too, as it is not moved by shrinking or swelling, shock, and vibration.

Furthermore, the seal is not prone to peeling and cracking. With all the good attributes of this sealant, it’s no wonder that it is usable both in a dry area or the section that contacts water. Hence, we can apply it on joints, access plates, rails, and others that are not exposed to sun rays.

I always go fishing or boating all summer long. With this sealant, I was able to use my boat not too long after fixing some cracks. Thanks to its fast curing formula! It only needs 24 hours to achieve complete curing. Just take a day off before plunging back into the water.

What surprises me about this sealant is the possibility of disassembling parts with no damages. It can be done due to its medium-level strength and, of course, the silicone. Since it is not permanent, you can make some adjustments when needed.

- Creates reliable bond on wood, aluminum, fiberglass, and gel coat

- Seal can’t be easily damaged by water and weather elements

- Flexible against shrinking or swelling, shock, and vibration

- Usable in dry and wet areas

- Fast curing within a day

- Can be disassembled due to medium-level adhesion

- Needs to follow the instruction for a smooth application

8. Sikaflex-291 Adhesive and Sealant

When attaching brackets and hull bolts, I turn to this sealant from SIKA. The bond that it creates can withstand the deteriorating effect of saltwater. Hence, I find the product useful as I always take my boat to the beach.

You may also use this sealant on other things aside from water vessels and marine hardware. It is certified by NFS for potable water, even accidentally mixed with edibles.

Usage seems limitless as you can have it in fixing solar panels, pool tiles, and rub rails. The areas that I repaired using this sealant remain intact for years. I once utilized it as a boat window sealant, and everything went well.

Regarding the application, you can complete the tasks with a sealant gun or using a brush. Either way, the strength of the bond is the same.

This is a sealant made of elastomeric adhesion, and it can be cured quickly. It will be favorable to you when you’re in a hurry and impatient. I find it easy to use but be extra careful when applying as it can get messy.

It adheres to metal, wood, fiberglass, and gel coat. Creating a light-duty bond is its forte, so if you plan to detach the sealed parts for replacement or reconstruction after some time, this should be your go-to product.

- Resistant to saltwater’s deterioration

- Safe to use approved by NFS

- Multi-purpose sealant for fixing solar panels, pool tiles, rub rails, etc

- Creates a light-duty bond for detachment later

- Cures quickly due to its elastomeric adhesion

- Require a careful application to avoid making a mess

9. Travaco RM330K Gluvit Epoxy Sealer

What convinces me to buy the Travaco Marine-Tex Epoxy Sealer is its repuation among boat owners. It turns out that this marine-grade agent is effective for curing aluminum, fiberglass, steel, and wooden parts of my boats. I would say that it’s the right marine sealant for aluminum boats based on my experience.

I used it to seal a three-decade-old aluminum boat, and it helped me transform the old friend into a new-looking vessel. I’m amazed at how it can cover pinholes and some minor cracks. Even thin cracks and tiny holes can’t surpass its sealing capability.

There are many benefits that I’ve gained from this epoxy sealer. The leaks on rivets and seams of my aluminum boat are gone for good. In my father’s case, he used it to stop the leaks around decks and cabins made of fiberglass.

It’s also reliable in combating galvanic corrosion on aluminum hulls. I applaud its ability to block abrasion, which happens when there are rocks. This sealer gives me peace of mind as the body of my boat is protected. You can use it on jet skis, canoes, and rowboats too.

Not to mention, water and parasites won’t be allowed to damage wooden surfaces. All it takes are a few strokes of the substance, and no molds will arise. You can paint the surface for a maximum shield against sunlight. But make sure you’ll use the appropriate kind of paint.

- Marine-grade sealant to cure hairline cracks and tiny holes

- Seals leaks on aluminum rivets and seams, fiberglass cabin, wooden surfaces, etc

- Resists corrosion and stops mold growth

- Allows painting for shielding against UV rays

- Flexes with movements of the vessels

- Needs to be nimble when applying due to quick-drying formula

10. 3M Marine Adhesive Sealant 4000 UV

I once used a super tough sealant and ended up making a mess on myself and my boat. I needed to do more cleaning than fixing its parts. Finding this 3M Marine Adhesive 4000 with medium strength is beneficial for me, as it allows modification.

What’s more to love about this product is its ability to stick on various surfaces. This sealant also works on plastic, fiberglass, wood, and deck fittings. Using it to hide screw holes is a success as I tried it once. You can assemble an electrical hatch with this sealant, too.

Moreover, I use it for the appropriate positioning of porthole frames. Window glazing and exterior sealing are a breeze with the help of this sealant.

Due to its superior UV ray resistance of this sealant, it’s ideal for cosmetic sealing. It can work as a below waterline sealant because it can resist saltwater. Furthermore, it can withstand weathering and joint movements.

I was able to cover the leaks, and the surface looks good with its white color. You may also paint the seal after application. Making a seal with this item is not that complicated, but it takes a lot of effort when taking out a small bead from the tube. Then give it 15 to 20 minutes to allow the sealant to get the job done.

- The medium-strength formula for adjustments later

- Can stick on various surfaces: plastic, fiberglass, wood, …

- Resistant to outdoor factors, including UV rays and water

- Ideal for cosmetic sealing

- Firm and rubbery texture that blocks water intrusion

- Take some effort to squeeze out small beads

11. Gorilla 100% Silicone Sealant Caulk

We can repair cracks and tiny holes using boat hull sealants. With the help of the Gorilla 100 Percent Silicone sealant, I was able to patch things up on my damaged boat.

You may be familiar with this brand, as it provides quality household accessories. Many have used this solution for fixing their doors, windows, kitchen, and bathroom. This product is also utilized in auto and marine parts since it is an expert in sealing and caulking.

I used it to fix some teeny weeny holes on the hull. This sealant saved me from a serious problem as there are dozens of holes. If those cracks are not fixed at an early stage, a section of my boat could have collapsed. This sealant is also great in ironing out issues on marine plumbing.

The best part is that the seal only needs half an hour to be ready for water exposure. As impatient as me, this feature exceeds my expectation with its quick-drying formula. Although the curing period only requires 24 hours, a waterproof seal completely forms. I love how it resists molds and mildew without turning yellowish.

The seal remains translucent even after drying. Based on its abilities, this Gorilla sealant is applicable for both indoor and outdoor use. The name includes a big animal with a strength that is similar to its bond. It doesn’t crack or shrink even for the longest time.

- Many uses (household, auto, and marine)

- Quick-drying and curing formula

- Resistance to molds and mildew

- Doesn’t turn yellowish

- Doesn’t crack or shrink

- Needs to be stored with a Q-tip to avoid hardening

12. Boat Life Sealant Lifeseal Tube

A round of applause to this sealant on how it prevents water from seeping through fittings and transom core! My dad has been using this product for decades. I’ve been following this practice as the fantastic results are tested and proven.

Many professionals use this sealant in making sailboats because of its permanent bond. I find it inconvenient to remove seals frequently when using marine silicone sealant. But with this product, the seal cleaves on the surface well without much maintenance.

I can say that the adhesion of this sealant is superb. The seal can remain for an extended period without shrinking, so you can depend on it to maintain your boat in a functional state. Since flexibility is one of its features, it can last despite movements and other outdoor elements.

This sealant impresses me further as it cures underwater. Even if you do this process, it won’t peel off, and it stays long just like how you put it above the waterline.

I like how we can buy it in small quantities to avoid wasting any amount. Yet, if you want it for a massive repairing project, you need to purchase it in a larger quantity.

- Prevents water seeping in boat parts with a permanent bond

- Promotes flexibility in movements

- Superb adhesion without shrinking

- Cures underwater without peeling off

- Comes in small quantity to prevent wasting

- Best for fiberglass and rebedding boat parts

- Need to buy more for bigger projects

What is Marine Sealant and How Does It Work

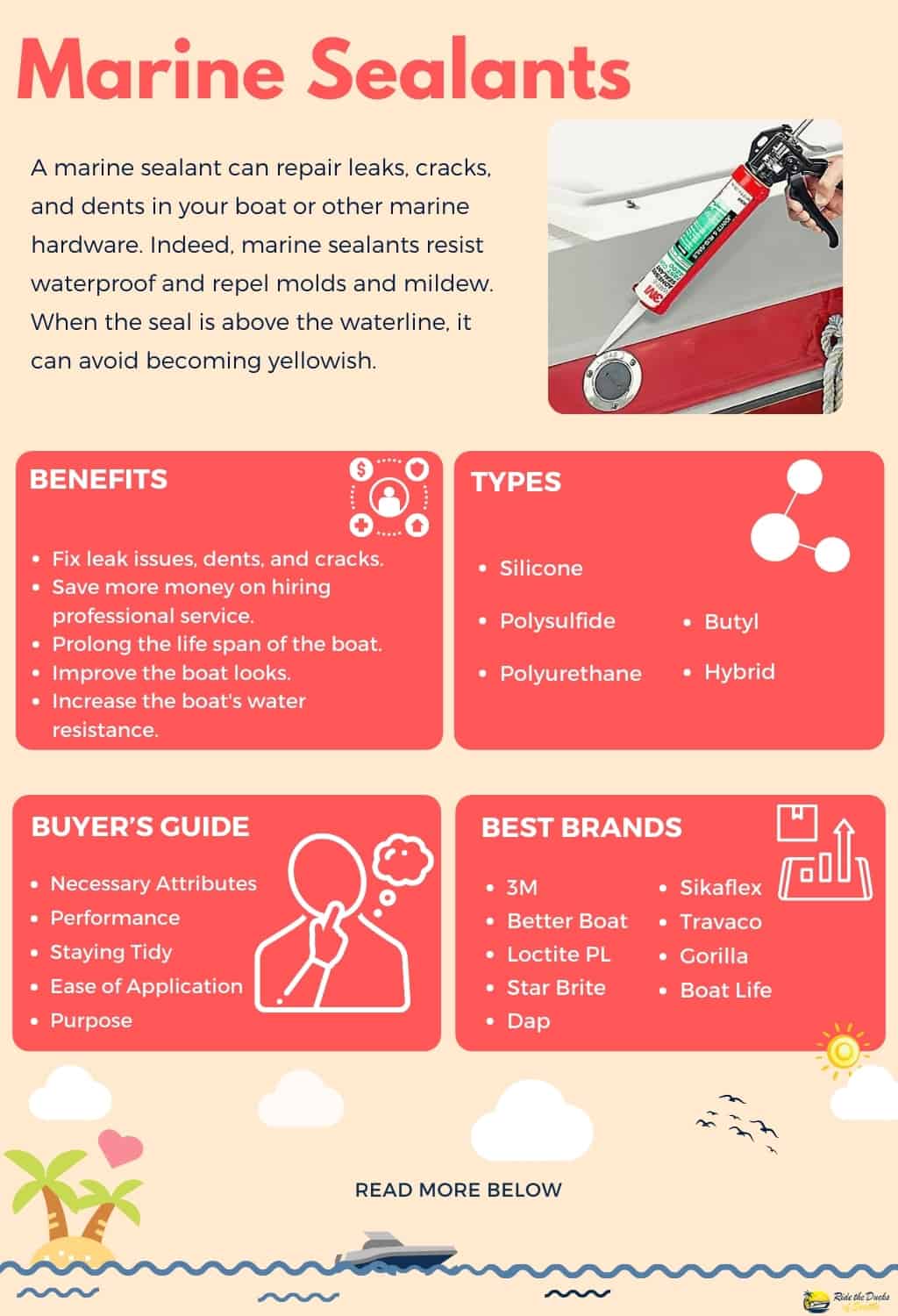

A marine sealant can repair leaks, cracks, and dents in your boat or other marine hardware. Indeed, marine sealants resist waterproof and repel molds and mildew. When the seal is above the waterline, it can avoid becoming yellowish.

You will find sealants in the solid and brittle form before it turns into tough, rubbery, and flexible consistency. Both strength and curing time vary from brand to brand. Some need hours, and the others would take days to be fully cured.

What’s great about a marine sealant is its ability to adhere to various surfaces like plastic, glass, bare metals, fiberglass, abraded rubbers, and non-oily type of wood. Flexibility is present, so its adhesion is reliable despite movements and vibrations.

Marine sealant impedes the penetration of water on the hull and other sections. So boat owners recognized the huge importance of this item on repairs. You can apply it on surfaces, joints, and some openings. It’s considered as a sort of mechanical seal.

A marine sealant is similar to caulking products. So the seal has the flexibility that goes with noise, heat transmission, and dust. Sealing is much sturdier and more durable. Since it can last long, you don’t need to pay a lot of money for repairs.

Types of Marine Sealants

There are three main types of marine sealants which are called silicone, polysulfide, and polyurethane. These materials can form a watertight and airtight seal on multiple surfaces. Thus, safeguarding the designated areas is what it does best.

The watertight seal it creates doesn’t only apply to a single type of surface. It can connect glass and wood or another combination. The boat surfaces are sealed together with the help of mechanical fasteners. This sealant is also intended to barricade noise and surge of electricity.

There are a plethora of marine sealants offered by different manufacturers. Aside from the three main types, you ought to know about butyl and hybrid. So you’ll be able to get the one that is suitable for the necessary repairs or projects.

Silicone

Silicone is referred to as a synthetic polymer that belongs to the rubber family. There are many reasons why it’s one of the favorite items used in maintaining a boat. It works wonders on being an insulator while it’s used to make gaskets. Silicone stays unmoved even with the presence of UV rays and heat.

This material may not be the best to use below the waterline as its adhesion is not too strong. If you find a permanent sealant bond inconvenient for you, better use a silicone sealant. It’s removable, so you can make adjustments and modifications.

Polysulfide

This material is a synthetic rubber that can do a lot of things for marine use. It can produce a tough mechanical bond while it combats sunlight streaks and the presence of oil or fuel. Boat owners also love the protection it provides as corrosion is fended off. It’s a wise choice for maintenance.

Some acknowledge it as a good electrical insulator. Its toughness is to the extent of resisting vibration, impact, shock, and thermal changes. Cosmetic sealing is also promoted by polysulfide as it’s fine to paint the seal right after application.

Polysulfide can flex to movements. It’s great for bedding fittings, antenna bases, and searchlights.

Polyurethane

The superior mechanical bond of polyurethane is what makes this material stand out among its peers. You will have the desired result as long as you apply it to the right surface. One thing is for sure. There will be no problem if you use it under the waterline or above it as it can resist harsh sunlight.

Take note that it’s not recommended to use acrylic perspex and some kinds of plastic glazing. It’s the one for you if you need to gain a permanent bond. This material is great for installing through-hull fittings, hull-to-deck joints, external keel attachments, and struts.

If the parts that you have to attach need to be separated in the future, don’t use polyurethane.

Butyl

The appearance of this material is similar to tape but it’s not adhesive. It’s like chewing gum but you can make a sealant out of it. You will find it easy to apply and remove. The strong point of butyl is its serviceability. Another advantage is that it’s not as messy as traditional sealants.

This material can last for so long up to 20 years. However, the appearance won’t be great. Since it’s susceptible to UV rays, it will look like a frayed chewing gum. You won’t be able to use it below the waterline based on the preceding case.

Hybrid

Manufacturers combined the elements to come up with a hybrid sealant. They try to figure out the pros of each type and retain them within their products. For instance, the heat resistance of silicone is partnered with the toughness of polyurethane. This combo gives a better bond but not that strong.

Benefits and Drawbacks of Using Marine Sealants

Every boat owner should invest in marine sealants to maintain boats and water vessels in functional condition. The watertight and airtight seal gives a lot of benefits for a boat. It takes care of the boat’s life span, sturdiness, and aesthetics.

A marine sealant can also work its way to intangible things like blocking noises and dampening vibrations. Here is the enumeration of the benefits.

- It’s the best choice to help you fix leak issues, dents, and cracks.

- Fixing leaks on your boat with a marine sealant won’t make you feel despair. Instead, you will be grateful to it as it saves you from spending more money on hiring professional service. The sealant won’t allow leaks and other issues to worsen as it can resolve issues.

- As mentioned, it prolongs the life span of the boat. The vessel becomes durable as the seal contributes to its resilience to harsh elements and some environmental factors.

- It improves the boat looks.

- Access to marine sealants is not difficult, so you can protect your boat in the easiest way possible and any time you want.

The drawback is when the user is confused. It starts with the different materials on the boat. Many varieties are available even on the side of metal surfaces like aluminum, stainless steel, zinc, and bronze. In this matter, don’t just get any marine sealant. See to it that it’s compatible with your boat.

Buyer’s Guide

Knowing the content of the marine sealant is essential to be able to get the right one. However, there are other things that you need to put into consideration before you purchase.

Necessary Attributes

When it comes to marine utilities, being waterproof is what every boat owner seeks. Flexibility to movements or vibration is something a seal should contain. On the other hand, the seal should not be prone to change of color or slowly turn into yellow.

Performance

This part is connected to the durability of the hold. The bond should be reliable to last for a long time.

Staying Tidy

Boats are taken outdoors, so it’s for the best that the seal can fight off molds, mildew, dirt, solvent, chemicals, and sun rays.

Ease of Application

Users like to find something that can be applied easily. A marine sealant is not an exemption in this common point of view.

Purpose

To avoid having regrets, identify your purpose of getting a marine sealant. Know the contents of the product to see if they are appropriate for the surface that needs fixing. Thus, you can fulfill the needs of your boat.

Care and Maintenance

Application of marine sealant necessitates care. In this aspect, you have to do it slowly and surely. This way, you can avoid making a mess.

You have to make sure that you apply it to specific areas. A random application can worsen situations, especially with the sealant that creates a permanent bond.

Since a marine sealant is part of the maintenance, you have to keep it near you. So it’s possible to fix issues right away. Once you see some leaks, dents, or cracks, spend time fixing them so you can stop the worse problems from arising.

Frequently Asked Questions

Who makes the top-rated marine sealant?

The ones who make the top-rated marine sealant are 3M, Better Boat, Loctite PL, Star Brite, Dap, Sikaflex, Travaco, Gorilla, and Boat Life.

Is marine sealant paintable?

Yes, you may paint marine sealant as long as it’s composed of polyurethane or polysulfide. See to it that you get the right kind of paint and apply it well as cracks may appear. If the seal goes well with the area, it’s best to leave it unpainted.

Do you need to seal marine plywood?

Though sealing marine plywood means more cost, it’s smart to do this procedure. Plywood is deemed as tough, resistant to moisture, and durable, but it still needs protection. All surfaces in water vessels should be covered as contact with water is inevitable.

When the plywood is above the waterline, it still needs to be protected. It’s best to choose an epoxy that is transparent when it dries. Less maintenance is required if you use sealant. that is clear or transparent

You need to prepare other things aside from epoxy, including acetone, sandpaper, a roller or brush, and a soft towel or cloth. Before sealing, the plywood needs sanding first. Then wipe the dust before applying the epoxy.

How do I apply marine sealant?

Planning every step of the way is essential in applying marine sealant, or it won’t come out successful.

- Make the surface dry and clean. Scrape or peel every bit of the previous sealant. Acetone can help with removing fastened surfaces.

- Take some time to read the label. Remember that sealants are different from each other. The needed time to ‘skin over’ or become fully cured varies. Know the product properties so you would know the proper steps of application and curing.

- Wearing protective gear is essential in the application of marine sealant. Don’t skip this step.

- To prevent mess and misplacing the sealant, the borders should be marked by a masking tape. Do it on the edges of the joint where you intend to apply the sealant. It would consume more time, but you’ll be thankful for it as cleaning up, later on, will not be so complicated.

You have to do this step even though you’ll be sealing a larger area. It’s still helpful even if you use a brush or a roller. Remember the adhesive ability of the sealant, so you don’t want to stick it just anywhere.

- Inspect the tube’s edges first when cutting the tip. Roughly do it in 45 degrees.

- To achieve a tidy outcome, use a caulking gun and push it while placing the sealant. Have control over how you squeeze to make sure that you get the right amount. Avoid releasing excessive sealant.

- The final part is dedicated to cleaning, modifying, and repairing. Swipe the bead with your gloved fingers to smooth it out. Wipe your fingers before doing another swipe. Then, you can remove the tape around the area of the application. Wipe the excess sealant with a dry cloth to finish the task.

The final phase also includes compressing the cured seal to ensure a watertight bond. In terms of thru-bolt assembly, only tighten the nuts and not the bolts.

How long does it take for marine sealant to dry?

The drying time or the curing time differs from product to product. This aspect is unchangeable as it’s based on the content of the sealant.

Schedule the repairs that you need to do when using a sealant that takes days to dry. It’s wise to plan before applying. Silicone sealants would typically turn dry in a matter of 24 hours. But you have to consider that the bond can be easily damaged when not given enough time.

However, the part that you used sealant on also matters whether you can use the boat right away or not. Knowing that polyurethane and polysulfide take longer to dry, the time can be shortened by moisture found in air or dew. You may also mist the glue line with water to quicken the drying.

Where can I buy?

Marine sealants are not hard to find. Stocks abound in local hardware stores or boating supply shops near you. However, better to check online if you’re keen on checking more choices. The internet has more to offer not only different sealants but information as well.

Only open a reliable website to get authentic and legitimate products. Don’t be too trusting on unknown pages to avoid getting fake ones. What’s best about shopping online is that you can find great deals and discounts. It’s delivered right on your doorstep without any hassle.

How to get marine sealant off hands?

You won’t have a hard time getting the marine sealant off your hands if you don’t give it a chance to dry. It doesn’t mean that you have to stop the application from time to time. Sloppy results will come up.

When the job is over, thoroughly wipe your hands with a paper towel. This step can remove big slobs of sealant, but somehow, you can’t get rid of all the bits. Once the sealant is partially dried on your skin, you have to put more work into removing it.

Try to chip or peel it off using your fingers. Another way to do it is by rubbing your hands together. You can remove the big chunks off your hands. Soften the remaining dried substance by washing your hands with warm water and soap a couple of times.

To remove every bit of the sealant, use a nail polish remover that contains acetone. You should do it in a ventilated area as acetone is a powerful solvent. Use a paper towel to rub off the specks of sealant. Lastly, wash your hands with warm water and soap.

Conclusion

The differences in contents used in the sealant lead to numerous products available. Hence, knowledge about the product is essential in picking the best marine sealant for your need.

Make sure you get the one that’s appropriate for the surface and your purpose. You must also know the properties to give it enough time to cure. The application should be done correctly so the adhesion would be reliable and the seal can last long.

I am passionate about water sports and technical fields, so combining both makes me interested in making contents about boat accessories. With my partner, we went on many trips and sports games together, which led us to think about how we can spread our joys and passions to many people.