Anchors are a vessel’s best friend for maneuvering and keeping it in a safe position in the water, featuring different anchor windlass parts and functions for proper operation.

Windless anchor systems feature at least five principal components, including a hawsepipe, winch, pawl bar, chain wheel drum, and dog clutch. The parts name might sound odd, but each plays a crucial role in managing and operating a vessel’s anchoring mechanism.

Don’t worry if you’re confused because we’ll shed light on these windlass terms (or parts) and their respective functions. Let’s begin.

Table of Contents

An Overview of Windlass Systems

Our first order of business is answering, “What is an anchor windlass?”

Ships lower a heavy object, known as an “anchor head,” to the bottom of the sea or other bodies of water. The anchor head resists water currents and keeps the vessel in place, preventing it from drifting.

The anchor of a 50-foot boat might only weigh 21 to 75 pounds, depending on the anchor head type and brand. Meanwhile, a 1000-foot ship’s anchor can weigh between 10 and 20 tons. For example, the 1090-foot USS Gerald R. Ford aircraft carrier has a 30,000-pound (15-ton) anchor head.

Imagine lowering a heavyweight object to the seafloor by hand and raising it again before the ship goes underway. The ship windlass addresses this concern by providing a mechanism for lowering and raising the anchor head to and from the seabed.

Simply put, a windlass anchoring system features a pulley mechanism. With this, people can raise or lower heavy objects without straining themselves. Initially patented by Archimedes, this pulley mechanism has since been upgraded to handle heavy anchor heads of larger ships, hence the advent of windlasses.

As such, the purpose of windlass is to ensure a more effective anchor head operation (lowering and raising). Its principal benefit is the effortless dropping, maneuvering, and drawing of the ship’s anchor. The crew won’t get tired operating the windlass while also guaranteeing safety.

Key Parts of an Anchor Windlass

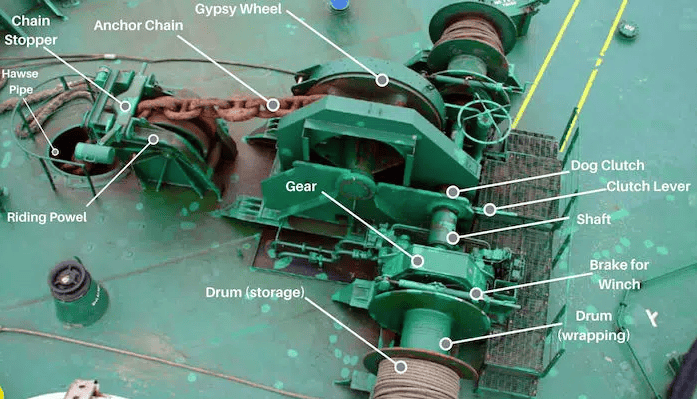

An examination of a typical anchor windlass diagram shows the system comprising the following key parts.

- Winch – a notched ring that contacts the anchor chain links

- Pawl bar – also called “Devil’s Claw,” an anchor rode restraining mechanism

- Dog clutch – a mechanism that engages or activates the gears

- Hawsepipe – a passageway for the anchor chain

- Chain wheel drum – an attachment component for the dog clutch

Here’s an image of these anchor windlass parts.

Functions and Roles of Each Part

Here are the functions and roles of each part of anchor windlass on ship units.

- Winch – The gypsy winch rotates the notched ring to move the anchor chain horizontally or vertically. It allows the crew to lower the anchor head into the water and raise it back up effortlessly.

- Pawl bar – This windlass component stops the anchor rode from sliding or falling back into the water

- Dog clutch – Similar to an automotive clutch mechanism, the dog clutch engages the gears to operate the windlass.

- Hawsepipe – This component provides a channel for guiding the anchor during operation.

- Chain wheel drum – The dog clutch attaches to this component, allowing the mooring winch and windlass to operate more efficiently.

Additional Parts and Accessories

The following are other anchor equipment windlass parts worth noting.

- Winch drum – accommodates a winch cable and rotates to activate the dog clutch.

- Anchor chain guide – allows the anchor chain to move through a channel for safe operation.

- Chainwheel – a component connected to the clutch to rotate the anchor chain.

- Electric motor – power the winch to activate it.

- Gears – wheel-like components of varying sizes to operate the winch.

How an Anchor Windlass Works

Learning how to use an anchor windlass requires understanding how it works. Although a vessel’s windlass has many components, the working principle is similar to a simple pulley system.

1. Anchor deployment process

Here are the steps for deploying the ship’s anchor. Raising it before going underway only requires reversing the steps.

- Deploying the ship’s anchor starts by flipping a switch to activate the electric motor that, in turn, engages the winch.

- Power in the winch rotates the drum and initiates action on the dog clutch.

- The dog clutch rotates the chainwheel at a predetermined speed and direction, allowing the windlass to run the anchor head and its rode down the ship.

- The gypsy mechanism applies the necessary force to control anchor rode movement throughout the winch operation.

- The anchor chain moves along the chain guide and through the system’s hewsepipe.

- The winch continues to operate until the anchor achieves the ideal anchor rode length.

- The Devil’s Claw engages to prevent the anchor rode from moving any further, ensuring it stays securely in place.

2. Power sources

Excluding manual systems, activating the anchor windlass requires power from one of three sources.

- Electricity – an electric windlass power source is a practical option, giving operators optimum convenience

- Hydraulics – a hydraulic windlass system is perfect for large vessels with multi-ton anchor heads because it’s more powerful and efficient

- Diesel – identical benefits as hydraulic power sources for windlass systems, amplifying anchor windlass capacity

Types of Anchor Windlasses

We can categorize anchor windlasses using two classification systems – one based on system orientation and the other according to the windlass’s operation.

1. Horizontal vs. Vertical

Horizontal anchor windlasses are easier to maintain and don’t take up too much space below decks. That said, it calls for more above-deck space and can get in the way.

Meanwhile, a vertical windlass is perfect for vessels requiring clutter-free decks, hiding the system below the deck. However, it calls for a large chain locker, which can take up a lot of space below the deck.

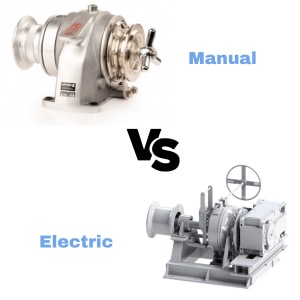

2. Manual vs. Electric

A manual anchor windlass is a cost-effective solution for small ships without onboard generators or electric/battery sources. Hand-driven systems are straightforward to install, although the operation is turtle-slow.

On the other hand, electric systems are convenient and quick. A single crewmember can operate the system without any fuss.

Installation and Maintenance

Anchor windlass demand observance of proper anchor windlass maintenance and installation procedures.

1. Proper installation

The following are the steps to proper windlass anchor installation.

- Review the anchor rode requirements for the windlass.

- Ensure the anchor rode will fall about a foot from below deck if using a horizontal windlass or 18 inches for a vertical design.

- Download a template plan from the internet, preferably one that matches your boat’s specifications.

- Drill holes for the gypsy, ensuring it aligns with the bow roller.

- Coat the gearbox bushing and windlass shaft with marine-grade lubricant or grease.

- Spray the motor and drivetrain with an anti-rust agent before sealing the mounting holes.

- Assemble the components, seal the windlass, and secure it to the deck.

- Read the manual for the wiring requirements.

2. Common issues with anchor windlass parts and troubleshooting

Anchor windlasses are mechanical devices subject to faulty operation and wear effects. Hence, boat operators must understand common issues and windlass anchor troubleshooting.

The windlass doesn’t operate.

- Check if the circuit breaker has tripped

- Determine if electricity is present in the system using a voltmeter.

- Test the batteries if they are drained or defective.

- If the batteries are good, the solenoid may be at fault.

- Deactivate and reactivate the controls several times.

- Evaluate the control box’s output if the controls have signals.

The windlass only works in one direction.

- Troubleshoot the issue using the steps above, except for circuit breaker and battery testing.

The chainwheel doesn’t rotate, even with the windlass working.

- Tighten the clutch.

- Bring the windlass to a mechanic for disassembly, inspection, and diagnosis.

FAQs

How often should I lubricate the anchor windlass components?

Check the windlass manufacturer’s recommendations for lubrication of the different components. Most experts recommend a weekly greasing of plain bearings, gear teeth, and nipples. Meanwhile, brake linings and other windlass components can benefit from monthly or quarterly lubrication.

What size anchor chain is suitable for my boat’s windlass?

You have two options.

First, you can use an anchor chain size chart and compare your boat’s overall length or beam. For instance, a 20-foot watercraft with an 8-foot beam should benefit from a ¼-inch chain rode.

The second method involves testing an anchor chain against the gypsy. You can uninstall the windlass from your boat and bring it to the store to determine the best anchor chain size. Alternatively, you can ask the store if they can lend you a sample anchor chain.

What is the location of anchor windlass?

The anchor windlass of large vessels is in a special chamber or compartment at the ship’s bow or fore section. Other watercraft install the windlass on the deck.

Considerations for choosing an anchor windlass

Choosing an anchor windlass requires boat owners to consider the watercraft type and size, displacement, chain size, anchor head weight, anchor hardware weight, and anchor rode. Anchor windlass brand, power source, and chain setup (all-chain vs. rope-chain combo) are also crucial.

How much anchor chain do I need for my windlass?

A good rule of thumb is to allocate eight meters of chain (about 26.25 feet) for every meter (or 3.3 feet) of water depth in the anchoring location. Transmuting it to feet will give us 7.95 feet (or eight feet) of anchor chain for every foot of water depth.

Conclusion

Learning the different anchor windlass parts and functions is crucial to choosing the right anchor management mechanism for boats and ships. Although the design looks complicated, its mechanism of action is as simple as a pulley lifting a heavy object from the ground.

We hope this article provided insights into how the different windlass components work individually and as part of a larger system. You can now install one on your watercraft.

Ten years of enjoying countless trips on boats never made me love them any less! So I am here to put all those experiences into good use for other boaters who want to have a safe and fun trip with their friends and families.