With so many tools, gadgets, and components that can be dizzying to first-time boat owners, it is natural for greenhorn boaters to ask, what is a boat bilge pump?

Marine bilge pumps draw fluids from vessel compartments and channel them through a discharge outlet. It is one of the most efficient ways to manage “swamping” and prevent capsizing the boat.

Table of Contents

A Boat’s Bilge Pump System

Building-tall waves, vessel damage, instability, and overloading are some reasons water enters a boat’s deck and floods its compartments. Machinery can also leak liquids like oil and fuel. Evacuating these liquids is vital to keep the watercraft from sinking.

The old-fashioned way to do this is by scooping accumulated fluids in the boat and dumping them out. A marine bilge pump system replaces manual labor by drawing unwanted in-boat liquids and discharging them outside.

Hence, we can define bilge as a mechanical device that “sucks” liquids from one compartment (i.e., inside the boat) and transfers them to another section or space—usually outside the vessel.

1. What does a bilge pump do?

You’ll know what a bilge pump does if you already understand how a pump, in general, works. Oil, water, fuel, and other fluids can accumulate in any vessel. Big and small, no watercraft is free from the risk of swamping.

The principal purpose of bilge pump systems is to remove unwanted liquids in the vessel’s interior and dump them exteriorly.

So, the next logical question is, how does it work? How does a marine bilge pump evacuate unwanted vessel liquids?

2. How do bilge pumps work?

It does not matter if your boat has a Johnson, Albin, Carver, Attwood, or Rule bilge pump. They all have a similar function or purpose – evacuate liquids accumulating inside the vessel and dump them overboard.

However, it is worth noting that bilge pumps vary in mechanisms of action, depending on their design.

For example, centrifugal bilge pumps feature rotating impellers that push liquids into the bilge pump system’s discharge unit. As more fluids pass through the discharge, more liquids enter the pump because of the resulting low pressure.

Other bilge pumps feature a diaphragm or piston to draw liquid into the pump through an inlet check valve. The system discharges the fluids when the piston or diaphragm pushes against them in the pump.

3. Location on a boat

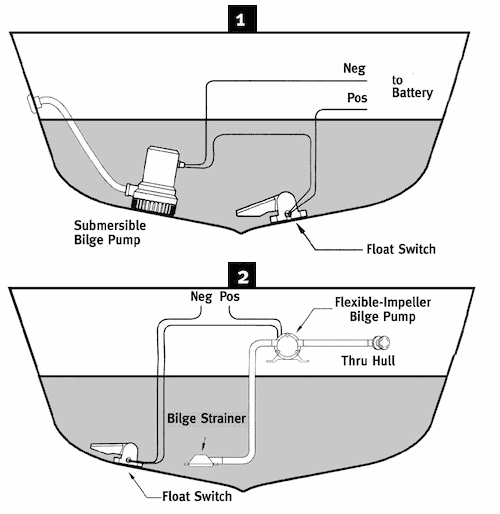

Where is the bilge pump located? Choosing the right spot for a bilge pump is crucial to maximizing its function – removing unwanted fluids and dumping them overboard.

Hence, the bilge pump location on boat units should be at the hull’s lowest point. Liquids naturally collect at the bottom-most section of any vessel. Placing the bilge pump at the lowest possible hull section is ideal.

Although the bilge pump must be at the boat hull’s lowest section, the system’s discharge must be at least 8 inches higher than the waterline. This arrangement will prevent external water from entering the pump through the discharge line.

Medium to large vessels should have at least two bilge pumps located on the starboard and port sides. Ideally, bilge pumps should have ample spacing between units to avoid flooding in emergencies.

Bilge pumps must also be accessible for periodic maintenance checks. Hence, if a sterndrive motor obstructs access to the bilge pump, you might want to relocate the device.

When and How to Turn on Bilge Pump

Learning how to use your boat’s bilge pump is hassle-free if you have an automatic mechanism. These devices have a switch or float that automatically activates the pump when unwanted liquid (i.e., water) in the bilge is present.

Meanwhile, manually operated bilge pumps require the user to “flip” a switch to turn it on. Some products have a “manual” and “auto” setting, allowing boaters to choose the most convenient method.

1. Legal requirements

States, cities, and municipalities have legislation regulating bilge pump systems. Hence, boat owners should check their local laws for the requirements.

In general, large vessels must have at least two bilge pumps. The bigger (or longer) the watercraft, the more bilge pumps it needs. Other factors include boating location and the availability of sleeping quarters.

In addition, as stated by maritime law, hand-operated bilge pumps must feature a pump long enough to discharge the water over the vessel’s side. It’s also required that power bilge pumps must have a self-priming design and be permanently linked to the vessel’s bilge main.

Here is a summary of the bilge pump requirements you must know.

| Watercraft Length | Number of Pumps | Bilge Pump Type | Bilge Pump Pumping Capacity |

| <9 feet | 1 | Portable hand-operated pump | 5 gallons per minute |

| Bailer | At least 0.2 gallons | ||

| <26 feet | 1 | Portable hand-operated | 5 gallons per minute |

| 26 feet to <40 feet | 1 | Portable hand-operated | 5 gallons per minute |

| 1 | Fixed power | At least 10 gallons per minute | |

| 40 feet to <65 feet | 1 | Portable hand-operated | 5 gallons per minute |

| 1 | Fixed power | At least 25 gallons per minute | |

| 65 feet to <120 feet and <100 gross tons | 2 | Fixed power | At least 50 gallons per minute (combined) |

| 120 feet to <180 feet and >100 gross tons | 2 | Fixed power | At least 400 feet per minute suction velocity per pump |

| >180 feet | 3 | Fixed power | At least 400 feet per minute suction velocity per pump (Each pump must have a minimum capacity of 25 GPM) |

2. Types of bilge pump

Most boaters classify a ship bilge pump according to its operation.

- Manual Bilge Pumps

A manual bilge pump for boat units gives the skipper or crew full control of the system’s operation. It can be hand-operated, making for an excellent emergency bilge pump in case of electric or auto bilge pump failure.

- Electric Bilge Pumps

An electric bilge pump runs on electricity and activates on its own when the water level is high enough to touch its float switch. Hence, most boaters call this type an automatic bilge pump, requiring no user input.

Marine bilge pumps can also come in three basic designs.

- Centrifugal Bilge Pumps

The bilge pump in ship units and large vessels has a centrifugal design, allowing the device to evacuate large volumes of water. A small boat bilge pump with a submersible centrifugal design is also available.

- Diaphragm Bilge Pumps

This type creates a vacuum that draws water or air through a valve and forces them out through another valve. A yacht bilge is usually of this type.

- Reciprocating Bilge Pumps

Also known as “piston” pumps, these bilge pumps are almost similar to its diaphragm counterpart. The piston moves up to create a vacuum and pulls water (and air) through the system before forcing them out.

However, because reciprocating bilge pumps’ pistons are not as efficient as the diaphragm varieties, they are not as popular.

Tips to Install and Maintain Your Bilge Pump

Here are several tricks to install a bilge pump system.

- Clean your vessel thoroughly before installing even a tiny bilge pump.

- Move your boat to a dry place before bilge pump installation.

- Mark your watercraft’s waterline as a reference for the bilge system’s discharge (must be 8 inches above the waterline).

- Always pre-measure the hose length to avoid bending and excess tubing.

- Opt for bilge pump kit for boat units with mounting platforms so you won’t have to drill the vessel’s hull.

- Always read and follow the bilge pump manufacturer’s installation instructions.

- Experiment with a bilge hose configuration that works best with your boat. You can use a combination of straight and corrugated bilge tubing.

As for maintenance, you should follow the practices below:

- Check the bilge pump automatic operation before every boating adventure. You can pour water into your vessel and determine whether the discharge port evacuates the water from the boat.

- Always inspect the bilge pump’s inlet display or screen box for any debris or loose particles that might clog the system. Remove these obstructions to prevent pump overheating and failure.

- Automatic pumps require periodic assessment of the electrical wiring, preferably before and after every trip.

- Assess the bilge pump discharge hose for kinks or splits and replace them as necessary.

Frequently Asked Questions

Do all boats have bilge pumps?

No, not all boats have bilge pumps. For example, no bilge pump for pontoon boat units exists because of these watercraft’s unique design. Each buoyant tube (the pontoon) is a self-contained and 100% sealed unit, freeing the vessel from water accumulation.

Should I leave bilge pump on?

No, it is unwise to leave the bilge pump on, especially if you have a manually-activated electric version. Although diaphragm and piston pump types can operate completely dry, these devices can still seize up and fail if they run for extended hours.

Automatic units are different because they only activate if in-boat water reaches a predetermined level. Hence, you can leave an automatic yacht or sailboat bilge pump on without worrying about the system failing.

Can you use a bilge pump for propulsion?

Yes, bilge pump propulsion is a mainstay in many remotely operated vehicles (ROVs), such as RC submarines, boats, and other miniature watercraft. These devices are sufficient for vessels requiring slow propulsion.

Conclusion

So, what is a boat bilge pump? Bilge pumps are indispensable tools for evacuating water and other unwanted liquids inside the vessel. This technology replaces human hands in scooping excess water and prevents the watercraft from capsizing.

Hence, all boats at risk for swamping (water entering the vessel) should have a bilge pump. You might not need this device if your watercraft is a pontoon or a similar boat.

Ten years of enjoying countless trips on boats never made me love them any less! So I am here to put all those experiences into good use for other boaters who want to have a safe and fun trip with their friends and families.